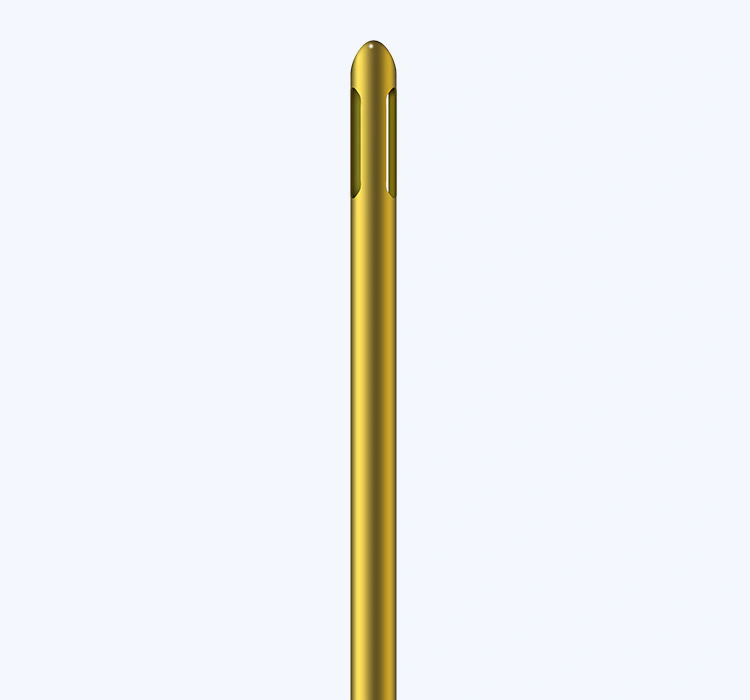

Sustainable Practices in the Manufacturing of Fat Transfer Cannulas

Sustainable Practices in the Manufacturing of Fat Transfer Cannulas

Sustainable manufacturing practices have become increasingly important in today's world as the environmental impact of various industries continues to be a growing concern. When it comes to the production of medical devices such as fat transfer cannulas, it is essential to ensure that sustainable practices are being implemented throughout the entire manufacturing process. In this article, we will take a closer look at some of the sustainable practices that can be incorporated into the manufacturing of fat transfer cannulas.

Use of Recycled Materials

One of the key sustainable practices in the manufacturing of fat transfer cannulas is the use of recycled materials. By using recycled materials, manufacturers can significantly reduce the amount of waste generated during the production process. Additionally, the use of recycled materials helps to conserve natural resources and reduces the environmental impact of the manufacturing process. In recent years, there has been a growing trend towards the use of recycled plastics in the production of medical devices, including fat transfer cannulas. By incorporating recycled materials into the manufacturing process, companies can make significant strides towards reducing their overall environmental footprint.

Energy-Efficient Production Processes

Another important sustainable practice in the manufacturing of fat transfer cannulas is the implementation of energy-efficient production processes. By optimizing production processes to minimize energy consumption, manufacturers can reduce their greenhouse gas emissions and overall environmental impact. This can be achieved through a variety of means, such as the use of energy-efficient machinery, the implementation of energy-saving technologies, and the adoption of renewable energy sources. By prioritizing energy efficiency in the manufacturing process, companies can significantly reduce their carbon footprint while also lowering their operational costs.

Waste Reduction and Recycling

Effective waste reduction and recycling programs are essential components of sustainable manufacturing practices for fat transfer cannulas. Manufacturers should strive to minimize waste generation through the implementation of lean manufacturing principles and efficient production practices. Additionally, any waste that is generated during the manufacturing process should be properly recycled or disposed of in an environmentally responsible manner. By prioritizing waste reduction and recycling, manufacturers can minimize their environmental impact while also potentially realizing cost savings through the reuse of materials and resources.

Supply Chain Sustainability

The sustainability of the supply chain is another critical consideration in the manufacturing of fat transfer cannulas. Companies must work closely with their suppliers to ensure that sustainable practices are being implemented throughout the entire supply chain. This can include engaging with suppliers who prioritize environmental stewardship, ethical sourcing, and fair labor practices. By prioritizing supply chain sustainability, manufacturers can ensure that their production processes are not adversely impacting the environment or local communities.

Product Lifecycle Considerations

In addition to sustainable practices in the manufacturing process, it is also important to consider the entire lifecycle of fat transfer cannulas. This includes aspects such as product packaging, transportation, and end-of-life disposal. Manufacturers should strive to design products and packaging that minimize environmental impact, such as using recyclable materials and reducing excess packaging. Additionally, companies should consider the environmental impact of transporting their products and work to optimize transportation logistics to minimize emissions. Finally, end-of-life disposal considerations are essential, and manufacturers should prioritize the development of products that are easily recyclable or biodegradable.

In summary, sustainable practices in the manufacturing of fat transfer cannulas are essential for reducing the environmental impact of the medical device industry. By incorporating recycled materials, prioritizing energy-efficient production processes, reducing waste, ensuring supply chain sustainability, and considering product lifecycle considerations, manufacturers can make significant strides towards environmental stewardship. By prioritizing sustainability in the manufacturing process, companies can minimize their overall environmental impact while also potentially realizing cost savings and operational efficiencies. Ultimately, the implementation of sustainable manufacturing practices for fat transfer cannulas is not only beneficial for the environment but can also contribute to the long-term success and resilience of the medical device industry.

Español

Español

Sales Manager : Kelly Zhou

Sales Manager : Kelly Zhou Email :

Email :  WhatsApp : +86 18067965386

WhatsApp : +86 18067965386