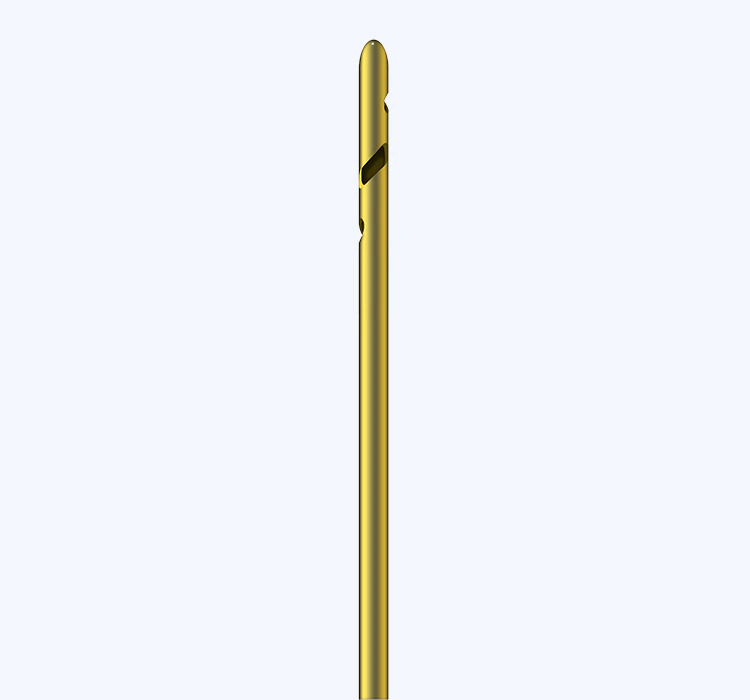

Sustainable Practices in the Manufacturing of Liposuction Cannulas and Instruments

The sustainable manufacturing of liposuction cannulas and instruments is becoming increasingly important in the medical industry. With a focus on reducing waste, lowering energy consumption, and utilizing eco-friendly materials, many companies are prioritizing sustainable practices in their production processes. This article will explore the various ways in which manufacturers are implementing sustainable initiatives in the manufacturing of liposuction cannulas and instruments, and the benefits that these practices bring to both the environment and the medical community.

Sourcing of Eco-Friendly Materials

One of the key components of sustainable manufacturing is the sourcing of eco-friendly materials for the production of liposuction cannulas and instruments. Traditionally, these medical devices have been made from materials such as stainless steel and plastic, which are not always environmentally friendly. However, many manufacturers are now seeking out alternative materials that have a lower environmental impact. For example, some companies are using recycled stainless steel or biodegradable plastics to produce their instruments. By incorporating these sustainable materials into their production processes, manufacturers are able to reduce their carbon footprint and contribute to the preservation of natural resources.

In addition to utilizing eco-friendly materials, some manufacturers are also implementing sustainable sourcing practices. This includes working with suppliers who adhere to responsible forestry and agricultural practices, as well as prioritizing the use of locally sourced materials to reduce the environmental impact of transportation. By carefully considering the origins of the materials used in the manufacturing process, companies are able to ensure that their products are not contributing to deforestation, habitat destruction, or other detrimental environmental effects.

Energy-Efficient Production Processes

Another important aspect of sustainable manufacturing is the implementation of energy-efficient production processes. The manufacturing of medical devices such as liposuction cannulas and instruments typically requires significant amounts of energy, from the operation of machinery to the heating and cooling of production facilities. To reduce their energy consumption, many manufacturers are investing in energy-efficient equipment and technologies.

For example, some companies are installing solar panels to generate renewable energy, implementing LED lighting to reduce electricity usage, and optimizing their production lines to minimize energy waste. By taking these steps, manufacturers are not only lowering their environmental impact but also reducing their operational costs. These energy-efficient initiatives contribute to the overall sustainability of the manufacturing process and demonstrate a commitment to responsible resource management.

Waste Reduction and Recycling

In the production of medical devices, waste generation is a significant concern. However, sustainable manufacturers are prioritizing waste reduction and recycling to minimize the environmental impact of their operations. One way in which companies are achieving this is by implementing more efficient production methods that generate less waste. This may involve optimizing manufacturing processes, reducing material trimmings, and finding innovative ways to use leftover materials.

Additionally, manufacturers are actively recycling materials such as metal shavings, plastic moldings, and packaging materials. By incorporating recycling programs into their production processes, companies are able to divert a significant amount of waste from landfills and reduce the demand for new raw materials. This not only benefits the environment but also contributes to the circular economy by promoting the reuse of materials within the manufacturing industry.

Adoption of Sustainable Packaging

In addition to the manufacturing of liposuction cannulas and instruments, sustainable practices extend to the packaging of these medical devices. Packaging plays a critical role in protecting products during transportation and storage, but it can also generate a considerable amount of waste. To mitigate this, many manufacturers are adopting sustainable packaging solutions that are designed to minimize environmental impact.

This may involve using recyclable or biodegradable materials for packaging, optimizing the size and shape of packaging to reduce material usage, and incorporating eco-friendly printing methods. Some companies are also exploring innovative packaging designs that eliminate the need for excess materials, such as utilizing reusable containers or incorporating sustainable materials into the packaging itself. By prioritizing sustainable packaging, manufacturers are able to further reduce their environmental footprint and contribute to the reduction of packaging waste.

Regulatory Compliance and Certification

As sustainability becomes an increasing priority in the manufacturing industry, regulatory bodies and certification programs are also playing a vital role in driving sustainable practices. Manufacturers of liposuction cannulas and instruments are required to adhere to strict guidelines and standards to ensure the safety and quality of their products. In recent years, there has been a growing emphasis on incorporating sustainable practices into these regulatory requirements.

For example, some certification programs now include criteria for sustainable sourcing, energy efficiency, waste management, and environmental impact reduction. By obtaining certifications that recognize their commitment to sustainability, manufacturers are able to demonstrate their adherence to responsible manufacturing practices and differentiate themselves in the market. This not only benefits the environment but also provides assurance to customers and end-users that the products they are using have been produced in an environmentally conscious manner.

In conclusion, the manufacturing of liposuction cannulas and instruments is undergoing a significant shift towards sustainable practices. By prioritizing the sourcing of eco-friendly materials, implementing energy-efficient production processes, reducing waste and recycling, adopting sustainable packaging, and obtaining regulatory compliance and certification, manufacturers are contributing to a more sustainable future for the medical industry. These initiatives bring benefits not only to the environment but also to the medical community, as they result in safer, higher quality products that align with responsible and ethical manufacturing practices. As the demand for sustainable medical devices continues to grow, it is evident that sustainable manufacturing is not only a priority but a necessity for the future of the industry.

Español

Español

Sales Manager : Kelly Zhou

Sales Manager : Kelly Zhou Email :

Email :  WhatsApp : +86 18067965386

WhatsApp : +86 18067965386