The Impact of Material Science on Fat Transfer Cannula Performance

Material science plays a crucial role in the development of medical devices, including fat transfer cannulas. These tools are used in aesthetic and reconstructive surgeries to transfer fat from one part of the body to another. The performance of fat transfer cannulas is greatly impacted by the materials used in their construction. In this article, we will explore the impact of material science on fat transfer cannula performance, and how advancements in material technology are shaping the future of these essential medical devices.

Understanding Fat Transfer Cannulas

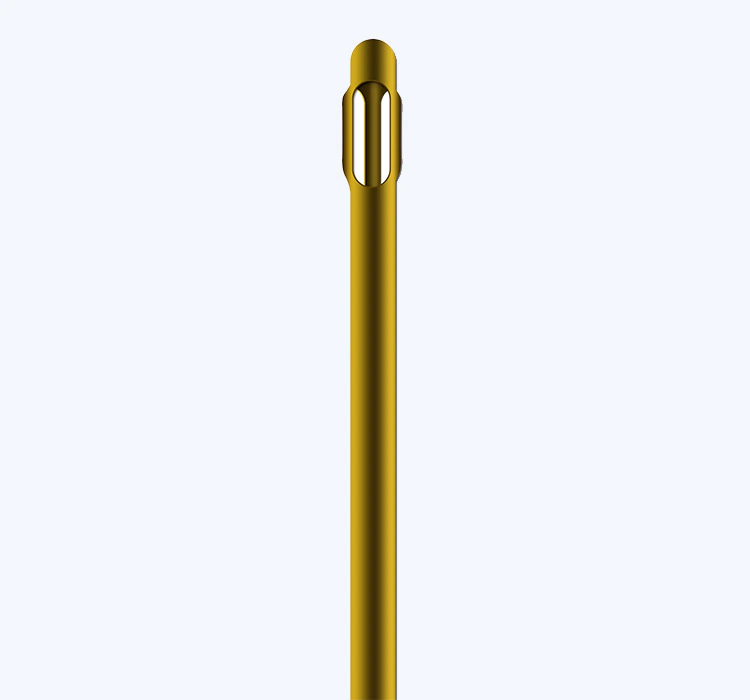

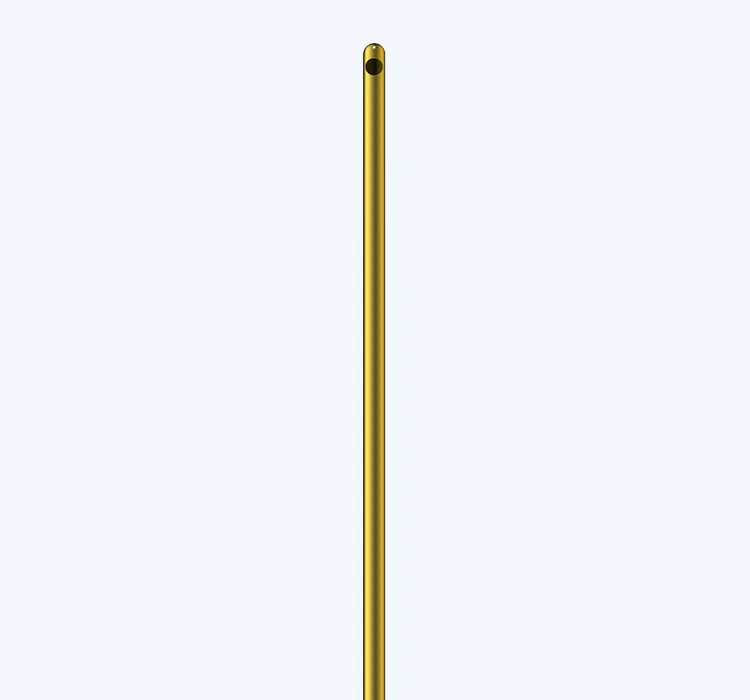

Fat transfer cannulas are thin, hollow tubes used for transferring fat from areas of excess to areas that require augmentation. These cannulas are commonly used in procedures such as liposuction, breast augmentation, and facial rejuvenation. The design and construction of fat transfer cannulas play a significant role in the success of these procedures, as they directly affect the efficiency and safety of the fat transfer process.

The Role of Material Science

Material science is a field that focuses on the study of materials and their properties. When it comes to fat transfer cannulas, the choice of materials used in their manufacturing is crucial. The materials used must be biocompatible, meaning they do not cause adverse reactions when in contact with the body. They must also be durable and easy to clean to ensure the safety and effectiveness of the medical procedures in which they are used.

One of the key concerns when it comes to material selection for fat transfer cannulas is the risk of tissue damage and trauma during the fat transfer process. This makes it essential for the materials to be as smooth and non-traumatic as possible to minimize the risk of complications for the patient.

Traditional Materials Used

Historically, fat transfer cannulas were made from stainless steel, a material known for its strength and durability. While stainless steel cannulas have been widely used in the past, they are not without their limitations. Stainless steel cannulas have a tendency to cause more trauma to the surrounding tissues due to their lack of flexibility and tendency to be more abrasive.

Advancements in Material Technology

In recent years, there has been a significant shift towards the use of more advanced materials in the manufacturing of fat transfer cannulas. One of the most notable advancements has been the introduction of cannulas made from medical-grade plastics and polymers. These materials offer a higher degree of flexibility and smoothness, reducing the risk of tissue trauma during the fat transfer process. They also offer the added benefit of being lightweight, making them easier for surgeons to handle during procedures.

Another key advancement in material technology for fat transfer cannulas is the development of coatings that further reduce friction and trauma during the fat transfer process. These coatings are designed to enhance the performance of the cannulas and improve patient outcomes.

The Future of Fat Transfer Cannulas

As material science continues to advance, the future of fat transfer cannulas looks promising. With ongoing research and development, we can expect to see even more innovative materials and technologies being used in the manufacturing of these essential medical devices. These advancements will not only improve the performance of fat transfer cannulas but also enhance the overall safety and efficacy of fat transfer procedures.

The impact of material science on fat transfer cannula performance is undeniable. Through the use of advanced materials and coatings, the efficiency and safety of fat transfer procedures have been significantly improved. As material technology continues to evolve, we can expect further advancements that will continue to shape the future of fat transfer cannulas and the medical procedures in which they are used.

Español

Español

Sales Manager : Kelly Zhou

Sales Manager : Kelly Zhou Email :

Email :  WhatsApp : +86 18067965386

WhatsApp : +86 18067965386