The Importance of Material Selection in Designing Fat Transfer Cannulas

The Importance of Material Selection in Designing Fat Transfer Cannulas

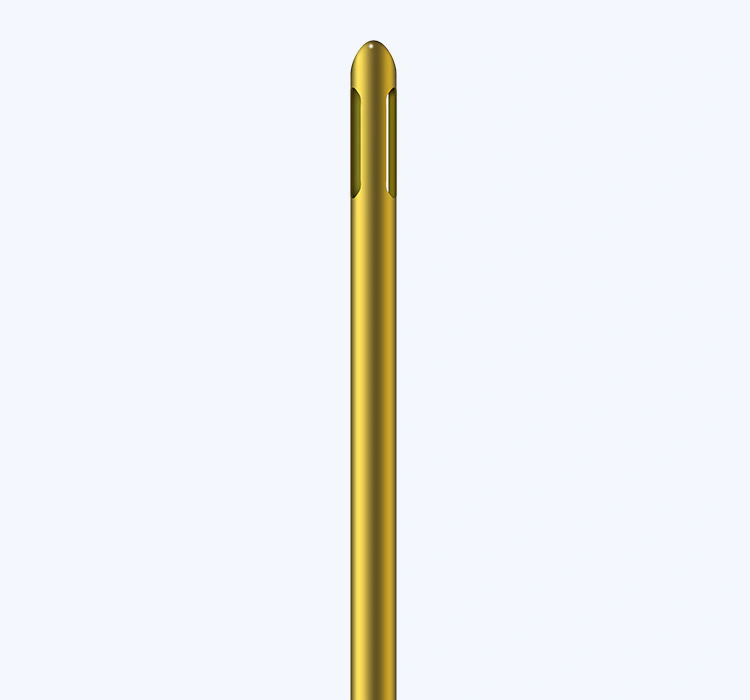

In the field of plastic surgery, fat transfer procedures have gained popularity in recent years as an effective method to enhance various areas of the body. One of the crucial tools in performing fat transfer procedures is the cannula, a thin tube used to remove and transfer fat cells from one part of the body to another. The design and material of the cannula play a critical role in the success of the fat transfer procedure, making material selection a vital consideration for plastic surgeons and medical device manufacturers.

Understanding Fat Transfer Cannulas

Fat transfer cannulas are hollow, stainless steel tubes of varying lengths and diameters, with one or more openings at the tip. These openings are used to harvest fat cells from the donor site and deposit them into the desired recipient area. The cannula is attached to a syringe, through which fat cells are extracted and later injected into the recipient site. The design of the cannula is essential in ensuring precise and controlled fat transfer, while minimizing trauma to the surrounding tissues and blood vessels. When it comes to the material selection for designing fat transfer cannulas, there are several key factors that need to be taken into consideration.

Selecting the Right Material for Fat Transfer Cannulas

The choice of material for fat transfer cannulas is critical, as it directly impacts the performance, durability, and safety of the device. Stainless steel, titanium, and plastic are commonly used materials for cannula construction, each with its own set of advantages and limitations. Stainless steel cannulas are widely used in fat transfer procedures due to their strength, flexibility, and ability to be easily sterilized. Stainless steel cannulas are available in various sizes and can be customized to meet the specific needs of the surgeon. However, stainless steel cannulas can be rigid, making them less suitable for delicate or intricate procedures.

Titanium cannulas are another popular option for fat transfer procedures, as they offer a unique combination of strength, flexibility, and biocompatibility. Titanium is much lighter than stainless steel, making it ideal for prolonged procedures, and it is less likely to cause a reaction in the body. However, titanium cannulas are more expensive to manufacture, and the material is not as widely available as stainless steel. Plastic cannulas, made from materials such as polycarbonate or polyethylene, are also used in fat transfer procedures. These cannulas are flexible and less likely to cause tissue trauma, making them suitable for delicate procedures. However, plastic cannulas may not be as durable or precise as metal cannulas, and they may need to be replaced more frequently.

Considerations for Material Selection

When selecting the material for designing fat transfer cannulas, several key considerations need to be taken into account. Biocompatibility is a crucial factor, as the material should not cause adverse reactions or inflammation when in contact with bodily tissues. Sterilizability is another important consideration, as the cannula must be thoroughly sterilized before each use to prevent infection and ensure patient safety. The material's durability, flexibility, and ease of customization are also vital factors that impact the performance and usability of the cannula in fat transfer procedures. Additionally, the cost and availability of the material are significant considerations for medical device manufacturers and plastic surgeons.

The material properties of fat transfer cannulas directly influence the outcome of the procedure, as well as the patient's safety and comfort. The choice of material must strike a balance between strength, flexibility, biocompatibility, and cost-effectiveness to ensure optimal performance. Ultimately, the chosen material for fat transfer cannulas should meet the specific requirements of the surgeon and the procedure, while prioritizing patient safety and satisfaction.

Advancements in Material Technology

Advancements in material science and technology have led to the development of innovative materials and coatings for medical devices, including fat transfer cannulas. Research and development in the field of biomaterials have focused on improving the mechanical properties, biocompatibility, and performance of materials used in medical devices. For example, the use of specialized coatings on stainless steel or titanium cannulas can enhance their lubricity, reduce tissue trauma, and minimize the risk of infection. These advancements allow for greater precision and control during fat transfer procedures, while also improving patient comfort and safety.

In recent years, the integration of nanotechnology into medical device materials has unlocked new possibilities for enhancing the performance of fat transfer cannulas. Nanomaterials and nanocoatings can improve the surface properties of cannulas, such as reducing friction, improving biocompatibility, and preventing bacterial adhesion. These advancements have the potential to revolutionize the design and material selection for fat transfer cannulas, leading to more efficient and safer procedures for patients.

Challenges and Future Directions

Despite the progress in material technology for fat transfer cannulas, there are still challenges that need to be addressed. One such challenge is the need for biodegradable materials that can safely dissolve or be absorbed by the body over time. Biodegradable cannulas would eliminate the need for a second procedure to remove the cannula from the recipient site, reducing patient discomfort and recovery time. However, developing biodegradable materials that meet the mechanical and performance requirements of fat transfer cannulas remains a significant hurdle for researchers and manufacturers.

Another area of focus for future development is the integration of smart materials and sensors into fat transfer cannulas. Smart materials can respond to changes in the surrounding environment, such as temperature, pH, or pressure, to enhance the precision and control of fat transfer procedures. Additionally, the incorporation of sensors into cannulas can provide real-time feedback to the surgeon, allowing for more accurate fat deposition and minimizing the risk of overcorrection or undercorrection. These advancements in material technology have the potential to elevate the safety, efficacy, and outcomes of fat transfer procedures, leading to greater patient satisfaction.

In summary, the material selection for designing fat transfer cannulas is a critical consideration that directly impacts the success and safety of the procedure. The choice of material must balance strength, flexibility, biocompatibility, and cost-effectiveness to meet the specific needs of the surgeon and the patient. Advancements in material science and technology have paved the way for innovative materials and coatings that enhance the performance of fat transfer cannulas, while future developments hold the promise of further improving the precision and safety of fat transfer procedures. As the field of material science continues to evolve, so too will the design and material selection for fat transfer cannulas, ultimately benefiting both surgeons and patients alike.

Español

Español

Sales Manager : Kelly Zhou

Sales Manager : Kelly Zhou Email :

Email :  WhatsApp : +86 18067965386

WhatsApp : +86 18067965386