The Role of Material Science in Enhancing Performance of Byron Cannulas

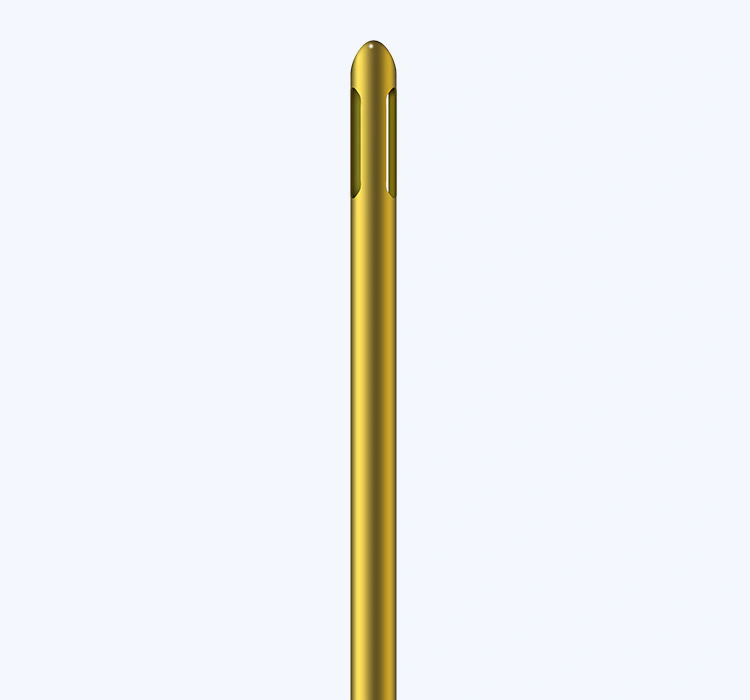

Material science plays a crucial role in the design and development of medical devices, including Byron cannulas. These small, flexible tubes are used in medical procedures to deliver or remove fluids from the body, and their performance is heavily dependent on the materials from which they are made. By leveraging the principles of material science, manufacturers are able to enhance the performance and functionality of Byron cannulas, ultimately improving patient outcomes and the overall quality of healthcare delivery.

The Importance of Material Selection in Byron Cannulas

The selection of materials for Byron cannulas is a critical aspect of their design and performance. These devices must be biocompatible, meaning they do not induce a negative reaction when in contact with living tissues. Additionally, they must possess the necessary mechanical properties to be inserted and removed from the body without causing trauma or discomfort to the patient. Material scientists carefully consider factors such as flexibility, strength, and resistance to corrosion when choosing materials for Byron cannulas.

Polyvinyl chloride (PVC) is a commonly used material for Byron cannulas due to its flexibility and compatibility with sterilization processes. However, ongoing advancements in material science have led to the development of alternative materials, such as silicone and polyurethane, which offer improved performance and biocompatibility. These materials have enabled the design of Byron cannulas with enhanced flexibility and kink resistance, leading to improved clinical outcomes for patients.

The Role of Surface Modification in Enhancing Performance

Surface modification techniques play a crucial role in enhancing the performance of Byron cannulas. By altering the surface properties of the material, manufacturers can improve factors such as biocompatibility, durability, and fluid flow characteristics. For example, the application of hydrophilic coatings to the surface of Byron cannulas can reduce the risk of thrombosis and improve the ease of insertion and removal. Similarly, antimicrobial coatings can help prevent infections and promote patient safety.

Material scientists are constantly exploring new methods for surface modification to further enhance the performance of Byron cannulas. Nanotechnology, for example, offers the potential to create surfaces with nano-scale features that can actively resist biofouling and improve fluid flow dynamics. By incorporating these advanced surface modification techniques, manufacturers can continue to improve the safety and effectiveness of Byron cannulas in clinical settings.

The Use of Additive Manufacturing in Byron Cannula Production

Additive manufacturing, also known as 3D printing, has emerged as a transformative technology in the production of medical devices, including Byron cannulas. This manufacturing process allows for the creation of complex, customized designs with unprecedented precision and speed. Material scientists are leveraging additive manufacturing to produce Byron cannulas with intricate internal geometries that optimize fluid flow and minimize the risk of blockages.

In addition to enhancing design capabilities, additive manufacturing enables the use of advanced materials that were previously difficult to process using traditional manufacturing methods. For example, bioresorbable materials can be used to create temporary Byron cannulas that dissolve within the body after fulfilling their function, eliminating the need for removal procedures. The ability to rapidly prototype and iterate on designs also accelerates the pace of innovation in Byron cannula development, leading to more effective and patient-centric solutions.

Advancements in Material Science for Multi-Lumen Byron Cannulas

Multi-lumen Byron cannulas, which feature multiple channels for the simultaneous delivery of different fluids or the aspiration of samples, are becoming increasingly important in medical procedures. The design and manufacturing of these complex devices rely heavily on advancements in material science to ensure reliable and safe performance. Material scientists are continuously researching and developing new materials and manufacturing techniques to meet the demands of multi-lumen Byron cannulas.

One of the key challenges in multi-lumen Byron cannula design is maintaining the integrity and functionality of each individual channel. Material scientists are exploring solutions such as coextrusion and composite materials to create multi-lumen cannulas with distinct fluid pathways that do not interfere with each other. Additionally, the use of shape memory polymers and smart materials that can adapt to changing conditions within the body is a promising area of research, as it could enable the development of responsive multi-lumen Byron cannulas that adjust their flow properties as needed.

Future Directions in Material Science for Byron Cannulas

Looking ahead, material science is positioned to continue playing a pivotal role in the advancement of Byron cannulas and other medical devices. As the field of biomaterials expands, new materials with enhanced biocompatibility, mechanical properties, and functionality will become available for use in Byron cannula design. The integration of smart materials and nanotechnology into Byron cannulas holds the potential to create dynamic, responsive devices that adapt to patient needs in real time.

Furthermore, material science will drive innovation in manufacturing processes, enabling more efficient and cost-effective production of Byron cannulas without compromising quality or performance. Additive manufacturing, in particular, will continue to revolutionize the way medical devices are designed and fabricated, leading to customized solutions that are tailored to individual patient needs.

In conclusion, material science is a driving force behind the continuous improvement and innovation of Byron cannulas. By applying principles of material science, manufacturers are able to develop cannulas that offer superior performance, safety, and patient outcomes. Ongoing research and development in material science will undoubtedly lead to further breakthroughs in Byron cannula design and production, ultimately benefiting healthcare systems and patients around the world.

Español

Español

Sales Manager : Kelly Zhou

Sales Manager : Kelly Zhou Email :

Email :  WhatsApp : +86 18067965386

WhatsApp : +86 18067965386