The Science Behind Fat Harvesting: Engineering Principles in Cannula Development

The science behind fat harvesting is a fascinating field that combines engineering principles with medical technology. One of the critical components in fat harvesting is the cannula, a device used to extract fat cells from the body. This article will explore the engineering principles behind cannula development, and how these principles have revolutionized the field of fat harvesting.

Understanding Fat Harvesting

Fat harvesting, also known as fat grafting or fat transfer, is a surgical procedure that involves removing fat from one part of the body and transferring it to another. This procedure has gained popularity for its ability to enhance various body parts, such as the breasts, buttocks, hands, and face. The extracted fat is typically harvested from areas with excess fat, such as the abdomen, thighs, or flanks. The fat is then purified and injected into the desired area to improve volume and contour.

The success of fat harvesting depends on the delicate process of fat extraction, processing, and injection. The cannula plays a crucial role in this process as it facilitates the efficient extraction of fat cells while minimizing trauma to the surrounding tissues. Developing an effective cannula requires a deep understanding of the engineering principles involved in the extraction process, as well as the specific requirements of fat harvesting procedures.

The Role of Engineering Principles

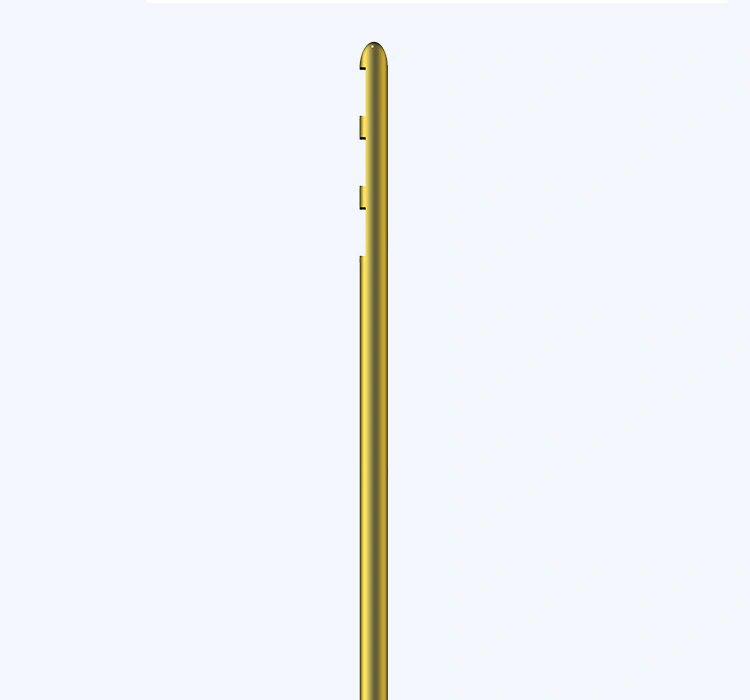

Engineers play a significant role in the development of cannulas for fat harvesting. They apply the principles of fluid dynamics, material science, and mechanical design to create cannulas that are efficient, precise, and minimally invasive. Cannulas must be designed to withstand the forces involved in fat extraction, while also being flexible enough to navigate through the body's tissues.

Fluid dynamics is a key consideration in cannula design, as the efficient extraction of fat cells relies on the flow of fluids through the device. Engineers use computational fluid dynamics (CFD) simulations to analyze the fluid flow inside the cannula and optimize its design for maximum fat extraction. This involves considering factors such as the size and shape of the cannula, as well as the properties of the fat tissue being extracted.

Material science also plays a critical role in cannula development. Engineers must select materials that are biocompatible, durable, and easy to clean. The cannula should also have a smooth surface to minimize tissue damage and reduce the risk of infection. Additionally, the flexibility of the cannula is essential for maneuvering through the body's tissues, which requires careful consideration of material properties and design.

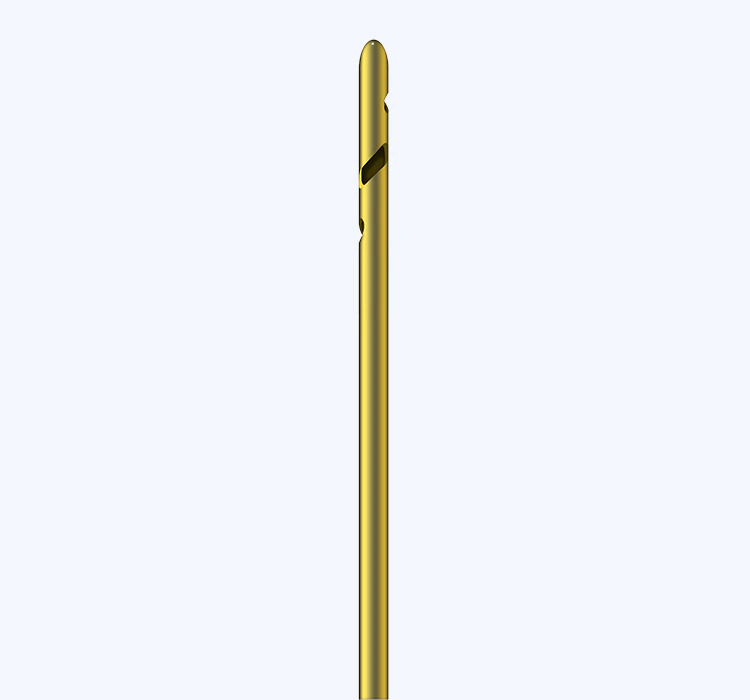

Mechanical design is another crucial aspect of cannula development. Engineers must ensure that the cannula is strong enough to withstand the forces involved in fat extraction, while also being thin enough to minimize tissue trauma. The design of the cannula tip is particularly important, as it determines the effectiveness of fat extraction and the level of trauma to the surrounding tissues. By applying principles of mechanical design, engineers can create cannulas that are both robust and minimally invasive.

Advancements in Cannula Technology

Recent advancements in engineering and medical technology have led to significant improvements in cannula design for fat harvesting. One of the most notable developments is the introduction of power-assisted liposuction (PAL) technology, which has revolutionized the fat extraction process. PAL involves using a cannula that vibrates at high frequencies, allowing for more efficient and less traumatic fat extraction. This technology has significantly reduced patient discomfort and recovery time, making fat harvesting procedures more accessible and less invasive.

Another significant advancement in cannula technology is the development of specialized cannulas for specific fat harvesting procedures. For example, facial fat grafting requires smaller, more precise cannulas to ensure accurate fat placement and natural-looking results. Engineers have developed specialized cannulas with finer tips and improved control, allowing for precise fat placement and contouring in delicate areas of the face.

Additionally, the integration of 3D printing technology has allowed for the customization of cannulas to meet the specific needs of surgeons and patients. Surgeons can now work with engineers to design and produce custom cannulas tailored to their unique fat harvesting requirements. This level of customization has led to more efficient and successful fat harvesting procedures, ultimately improving patient outcomes and satisfaction.

Challenges and Future Directions

While significant progress has been made in cannula development for fat harvesting, several challenges remain. One of the key challenges is optimizing fat processing and purification techniques to ensure the highest quality fat for injection. Engineers and scientists continue to explore new methods for purifying fat cells and enhancing their survival rate after transplantation. Additionally, there is ongoing research into improving the integration of fat cells with the surrounding tissues, which is crucial for long-term results and patient satisfaction.

In the future, advancements in robotics and automation may play a significant role in the evolution of cannula technology for fat harvesting. The integration of robotic-assisted systems could improve the precision and control of fat extraction and injection, leading to more consistent and predictable results. Furthermore, advancements in nanotechnology and biomaterials may provide opportunities for the development of even more advanced and biocompatible cannulas, further enhancing the effectiveness and safety of fat harvesting procedures.

Conclusion

The engineering principles behind cannula development for fat harvesting are essential for the success and advancement of this field. Engineers play a critical role in designing cannulas that are efficient, precise, and minimally invasive, ultimately improving patient outcomes and satisfaction. Recent advancements in cannula technology, such as power-assisted liposuction and specialized cannulas, have significantly improved the fat harvesting process, making it more accessible and less invasive for patients.

As the field of fat harvesting continues to evolve, engineers will play an integral role in addressing remaining challenges and guiding future directions. By applying principles of fluid dynamics, material science, and mechanical design, engineers can continue to improve cannula technology, ultimately enhancing the effectiveness and safety of fat harvesting procedures. With ongoing advancements in technology and collaboration between engineers, scientists, and surgeons, the future of fat harvesting looks promising, with the potential to further improve patient outcomes and satisfaction.

Español

Español

Sales Manager : Kelly Zhou

Sales Manager : Kelly Zhou Email :

Email :  WhatsApp : +86 18067965386

WhatsApp : +86 18067965386