The Science of Liposuction: Engineering Principles Behind Cannula Design

The Science of Liposuction: Engineering Principles Behind Cannula Design

Liposuction is a popular cosmetic procedure that helps people achieve their desired body shape by removing excess fat from areas such as the abdomen, thighs, and buttocks. While many people are familiar with the concept of liposuction, the engineering principles behind the design of the cannula, the main tool used in the procedure, are less well-known. In this article, we will explore the science behind liposuction and the engineering principles that guide the design of the cannula.

The Evolution of Liposuction Technology

Liposuction has come a long way since its introduction in the 1960s. The earliest methods of liposuction involved manually scraping and suctioning fat through small incisions in the skin. These methods were not only labor-intensive but also carried significant risks of bleeding and tissue damage. As technology advanced, new techniques such as ultrasound-assisted liposuction (UAL) and laser-assisted liposuction (LAL) were developed to make the process more efficient and less invasive. The evolution of liposuction technology has also led to advancements in cannula design, with engineers constantly seeking to improve the efficiency and safety of the procedure.

Understanding the Role of the Cannula

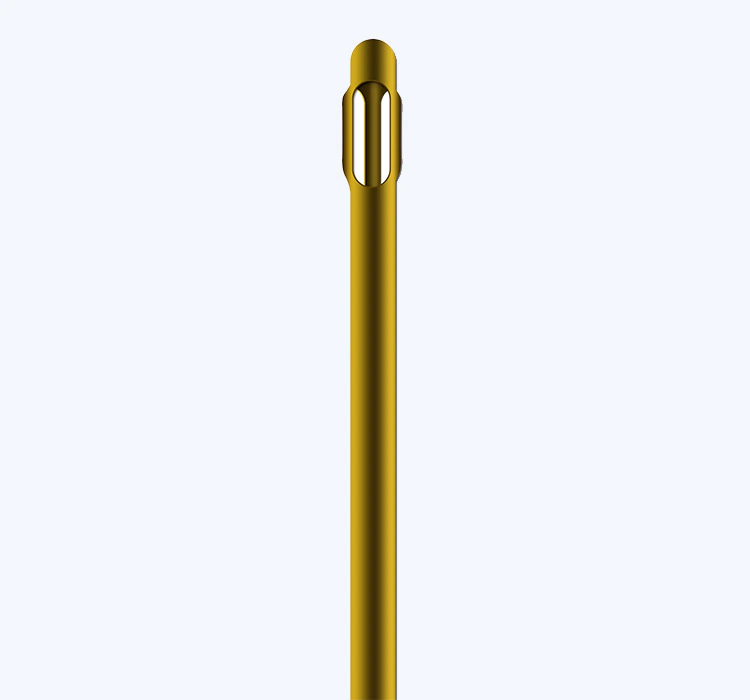

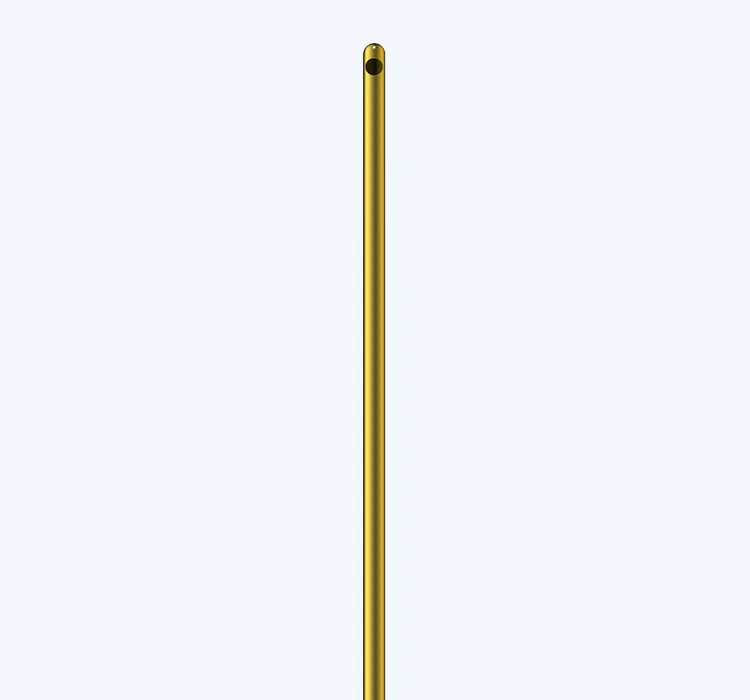

The cannula is the primary tool used in liposuction, and its design plays a crucial role in the success of the procedure. A typical cannula consists of a hollow tube with a small, blunt tip and multiple side ports for suction. The size and shape of the cannula, as well as the configuration of the side ports, can vary depending on the specific technique and the area of the body being treated. The goal of the cannula is to efficiently remove fat cells while minimizing trauma to the surrounding tissues. Engineers must carefully consider these factors when designing a cannula to ensure that it effectively meets the needs of both the surgeon and the patient.

Engineering Principles Behind Cannula Design

The design of a liposuction cannula is guided by several key engineering principles. Firstly, the size and shape of the cannula must be carefully tailored to the specific characteristics of the target area. For example, smaller cannulas are typically used for more delicate areas such as the face or neck, while larger cannulas may be used for larger areas such as the abdomen or thighs. The configuration of the side ports also plays a critical role in the efficiency of fat removal. Engineers must optimize the placement and size of the ports to ensure effective suction while minimizing tissue trauma.

In addition to size and shape, the material used to manufacture the cannula is another important consideration. Cannulas are typically made from medical-grade stainless steel or plastic, both of which have their unique advantages and limitations. Stainless steel cannulas are known for their durability and ability to withstand repeated sterilization, while plastic cannulas may offer greater flexibility and reduced risk of tissue damage. By carefully selecting the appropriate material for the cannula, engineers can ensure that it meets the necessary functional requirements while maintaining the highest standards of safety and reliability.

The development of new cannula designs is also influenced by advancements in manufacturing techniques. 3D printing, for example, has opened up new possibilities for creating complex, customized cannula shapes that were previously difficult or impossible to achieve using traditional manufacturing methods. By leveraging the capabilities of advanced manufacturing technologies, engineers can create cannulas that are better tailored to the specific needs of patients and surgeons, ultimately enhancing the overall effectiveness and safety of the liposuction procedure.

The Future of Cannula Design

As technology continues to advance, the future of cannula design holds great promise for further improving the outcomes of liposuction procedures. Engineers are exploring the use of advanced materials such as shape memory alloys and biocompatible polymers to create cannulas with enhanced performance and biocompatibility. Furthermore, the integration of sensors and real-time feedback systems into cannula design may enable surgeons to have better control and visibility during the procedure, leading to more precise fat removal and reduced risk of complications. The future of cannula design is not only about enhancing the efficiency of fat removal but also about ensuring the highest standards of patient safety and satisfaction.

In conclusion, the science of liposuction is deeply intertwined with the engineering principles that guide the design of the cannula. The evolution of liposuction technology has led to significant advancements in cannula design, with engineers constantly seeking to improve the efficiency and safety of the procedure. By carefully considering factors such as size, shape, material, and manufacturing techniques, engineers can create cannulas that are better tailored to the specific needs of patients and surgeons, ultimately enhancing the overall effectiveness and safety of the liposuction procedure. As technology continues to advance, the future of cannula design holds great promise for further improving the outcomes of liposuction procedures, ultimately leading to better patient satisfaction and safety.

Español

Español

Sales Manager : Kelly Zhou

Sales Manager : Kelly Zhou Email :

Email :  WhatsApp : +86 18067965386

WhatsApp : +86 18067965386