Related Products

Dino Medical – Leading Liposuction Cannula Manufacturer | Years of Specialized R&D

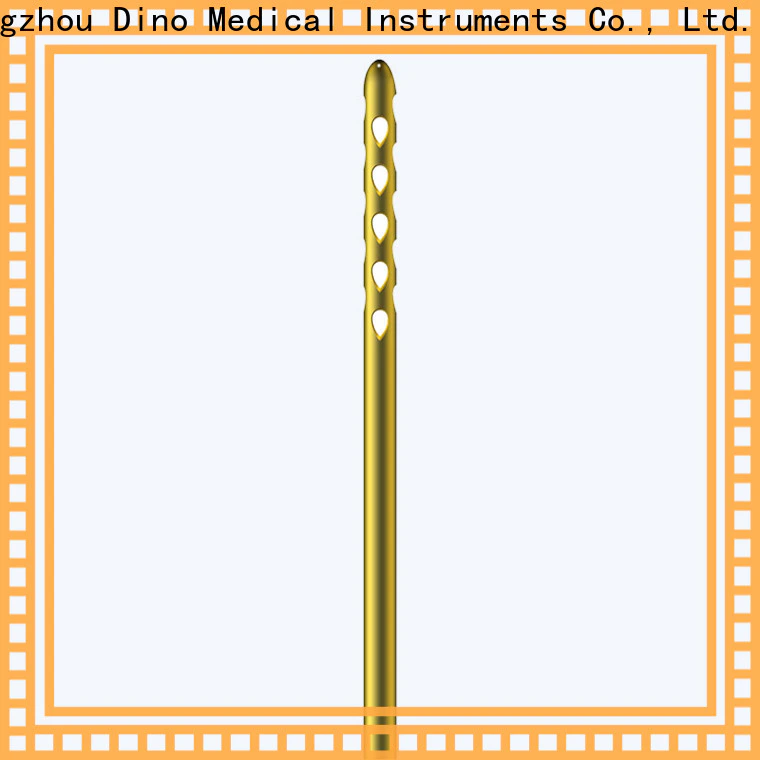

| Model: | 20HOLE Tip Liposuction Cannula. |

|---|---|

| MOQ: | 20pcs. |

| Payment terms: | 30% deposit and remainder before shipping. |

| Delivery time: | 3-30 days depends on the quantity of order. |

| Shipping Port: | Shanghai/ Ningbo. |

| Certificates: | CFDA. |

Copyright © 2025 Hangzhou Dino Medical Instruments Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a responsefrom us via email. Please be sure to leave yourcontact details so that we can better assist