Product Comparison

Dino Medical Instruments insists on the use of high-quality materials and advanced technology to manufacture micro cannulas manufacturer. Besides, we strictly monitor and control the quality and cost in each production process. All this guarantees the product to have high quality and favorable price.Compared with similar products, Dino Medical Instruments's micro cannulas manufacturer has the following advantages.

Company Advantages

1. Dino is accurately manufactured based on the principles of lean production.

2. The product is of high quality and can withstand rigorous quality and performance testing.

3. Product quality has been improved due to the implementation of a strict quality management system.

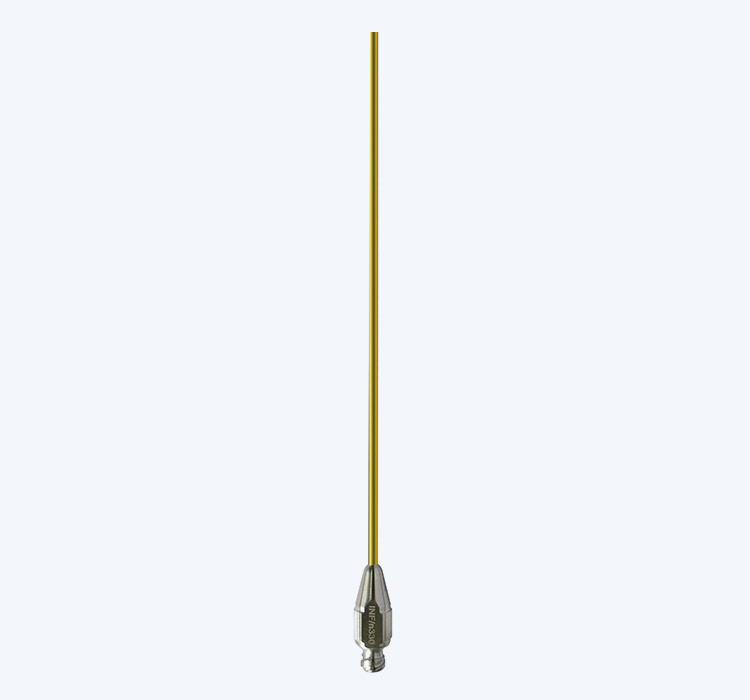

4. Without the high quality performance, circular hole cannula can not be so popular in this market.

5. The quality of products is the key to Hangzhou Dino Medical Instruments Co., Ltd.'s victory in market competition.

Company Features

1. Hangzhou Dino Medical Instruments Co., Ltd. designs and manufactures high quality and reliable with the main focus on realizing customer needs.

2. Hangzhou Dino Medical Instruments Co., Ltd. has a sound management system and abundant production experience.

3. In every detail of the work, Hangzhou Dino Medical Instruments Co., Ltd. follows the highest ethical standards. Inquire online! Instead of choosing the profit-driven strategies, our company insists on holding the strategy of promoting corporate social responsibility. In response to the ever-increasing environmental problems, we make sustainable plans for reducing water and air pollution, as well as energy saving. Inquire online! Winning more overseas market share is what we pursue now. Under the technological support, we will strive hard to win over customers by quality and service.