How about production process for liposuction cannulas?

2020-12-25

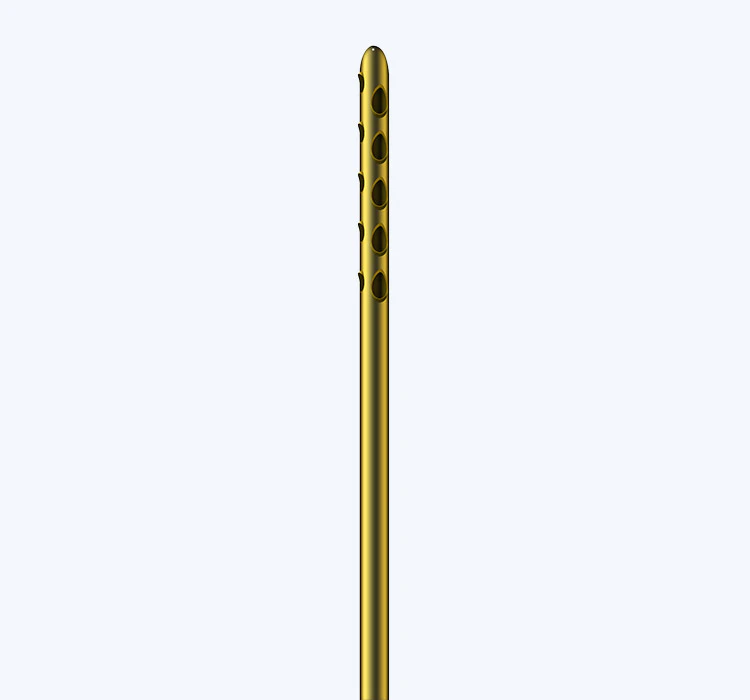

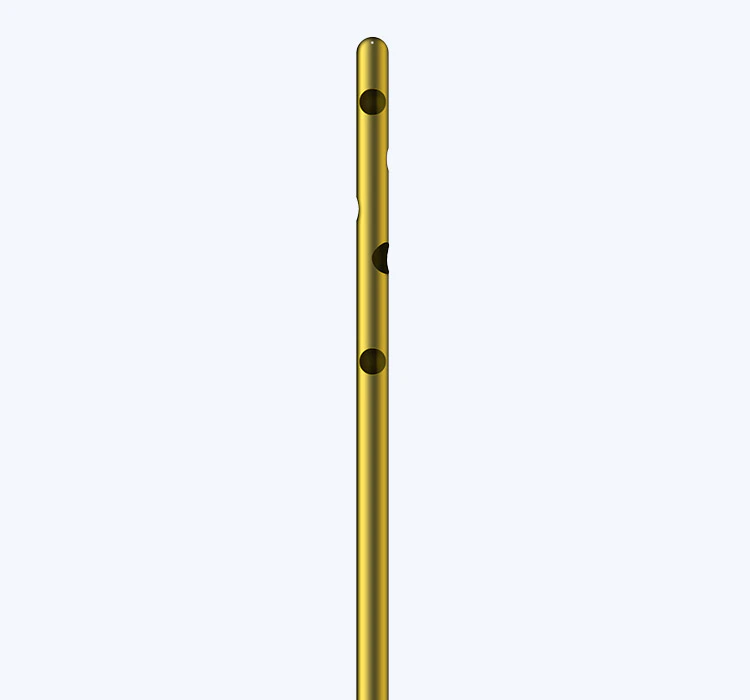

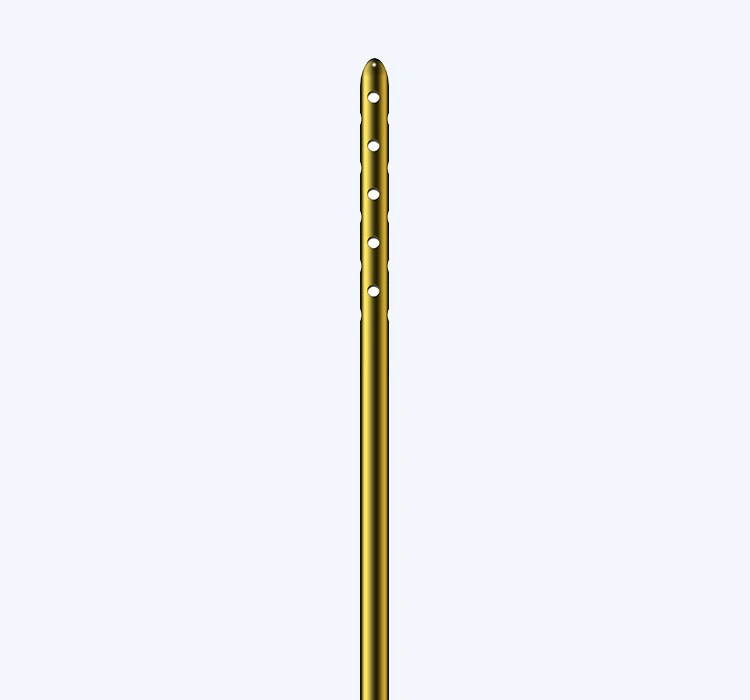

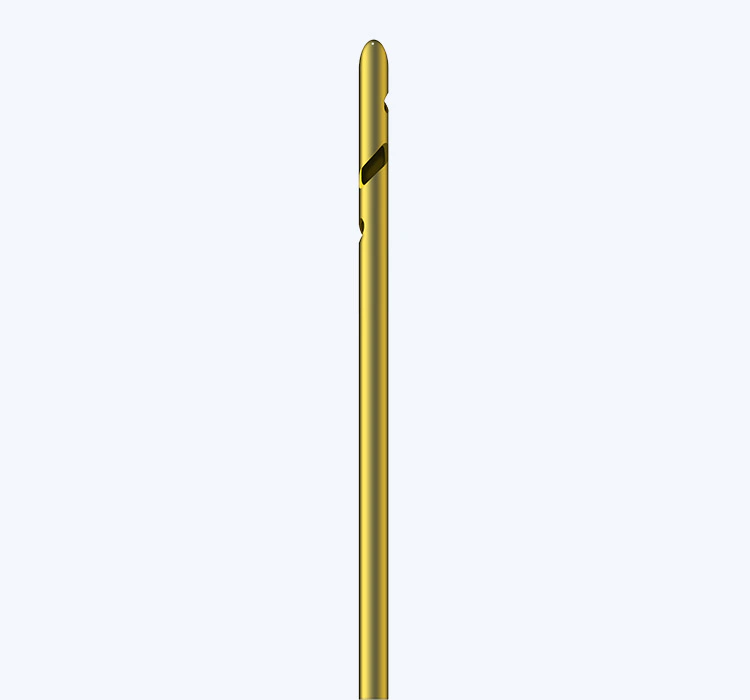

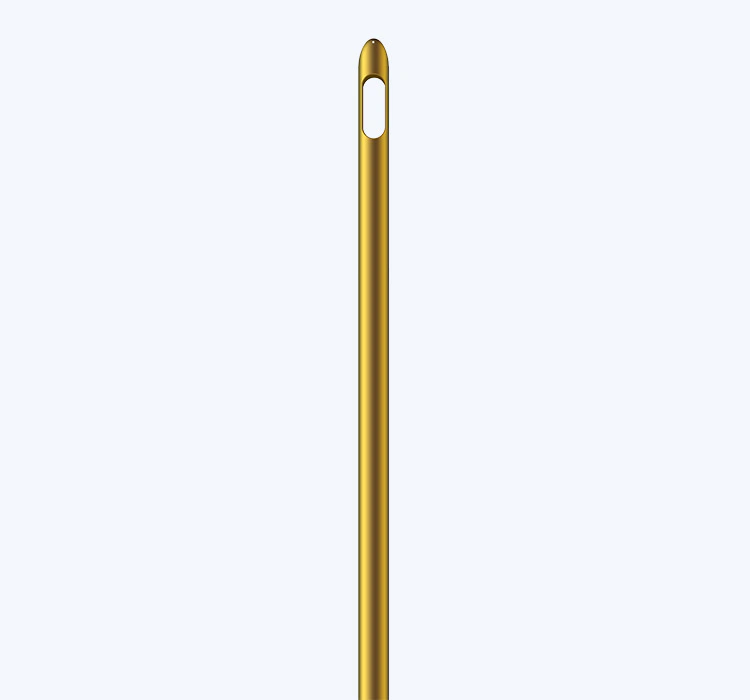

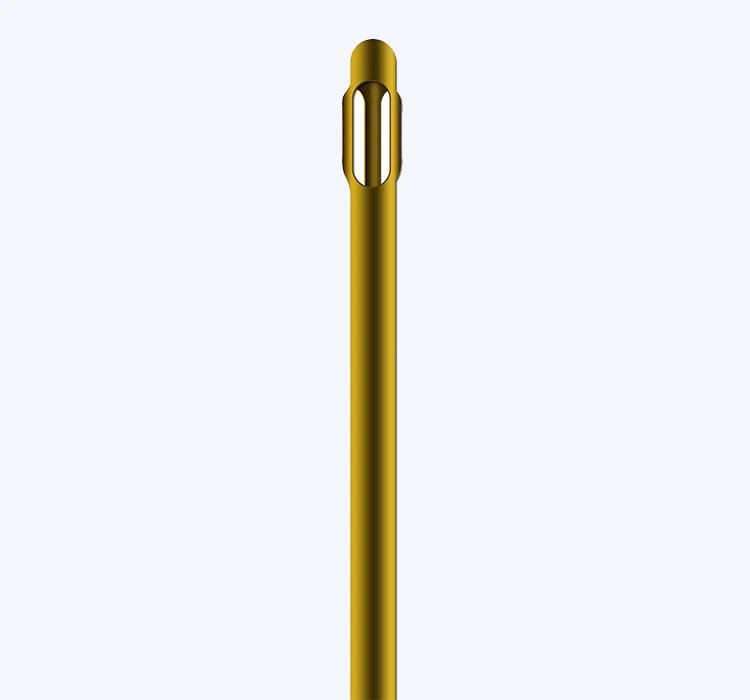

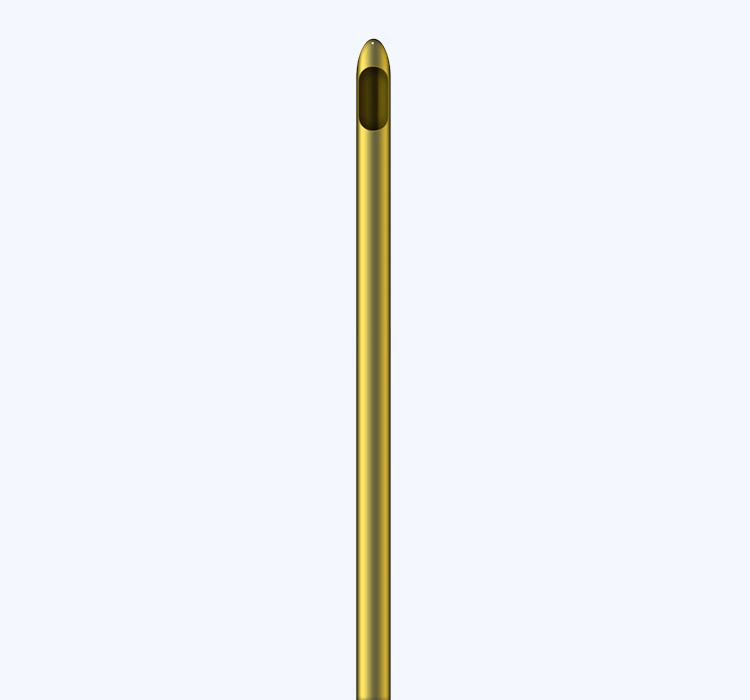

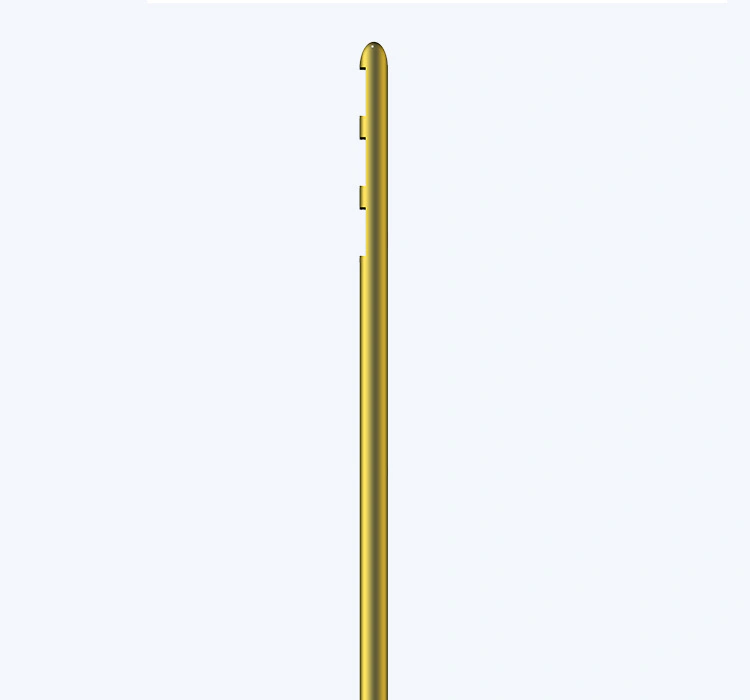

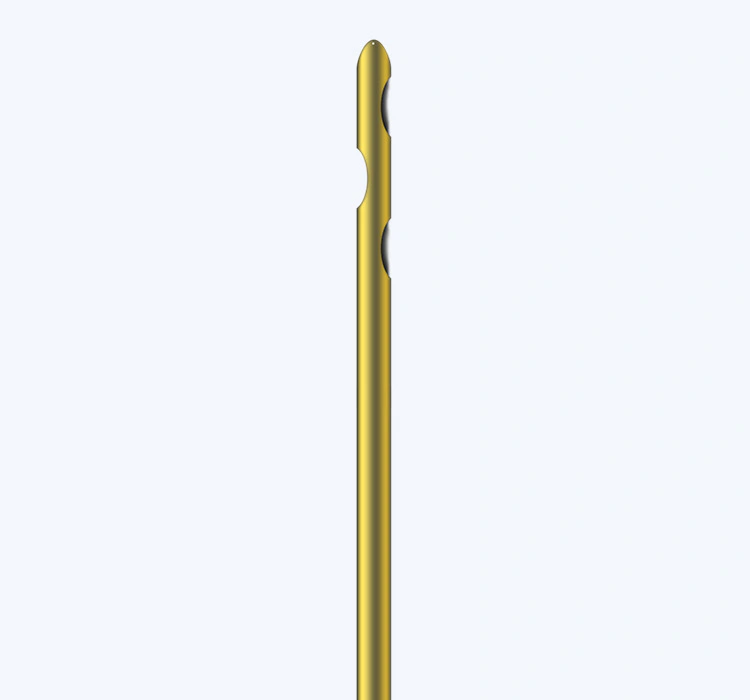

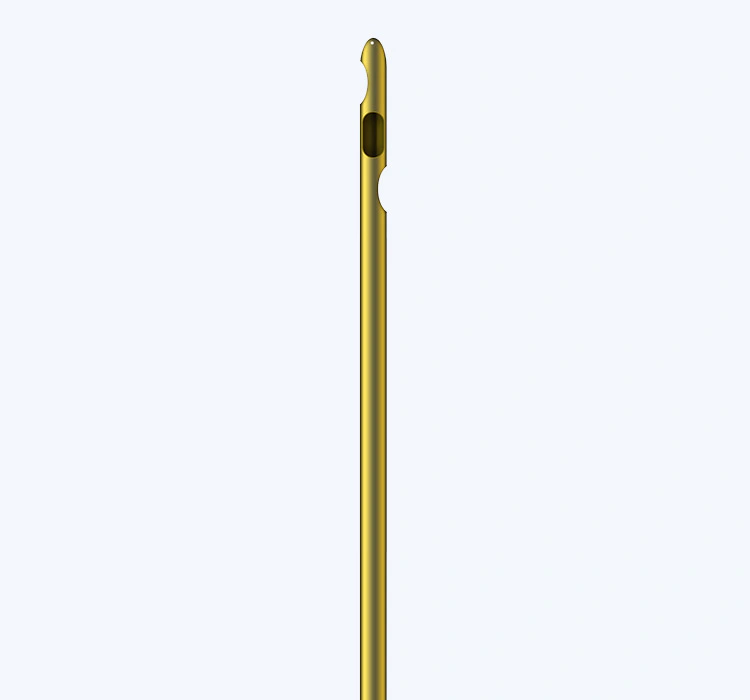

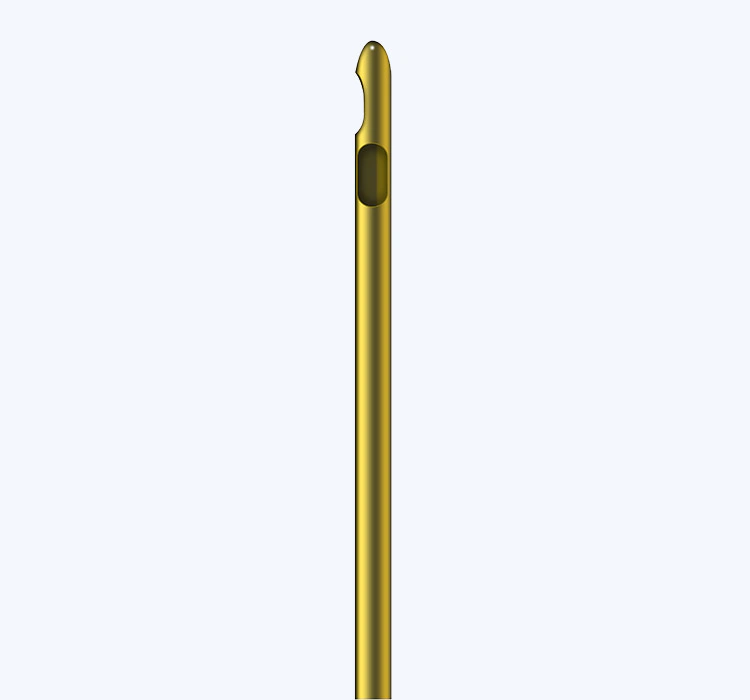

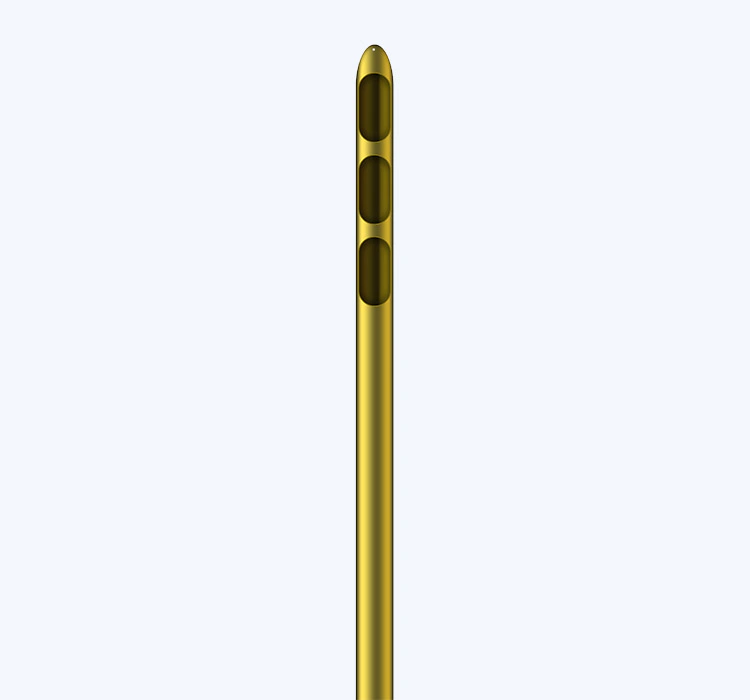

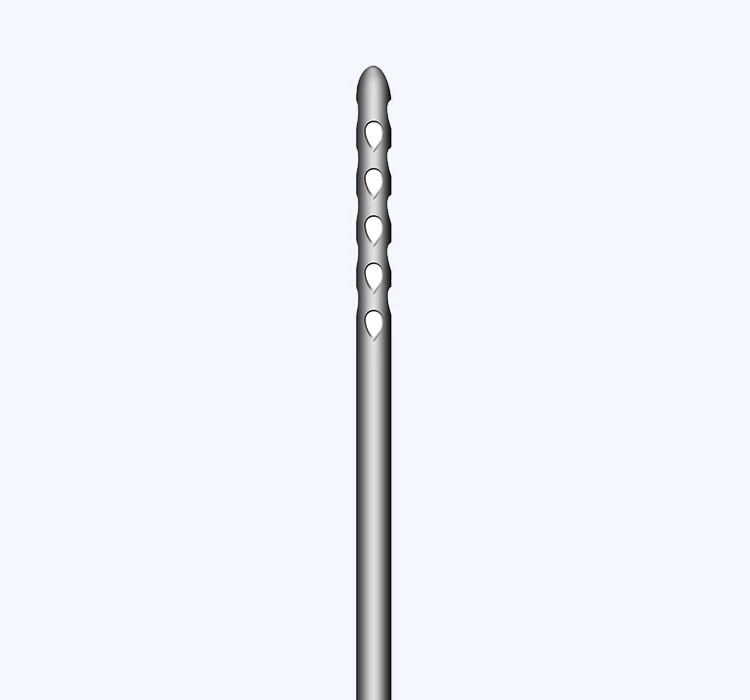

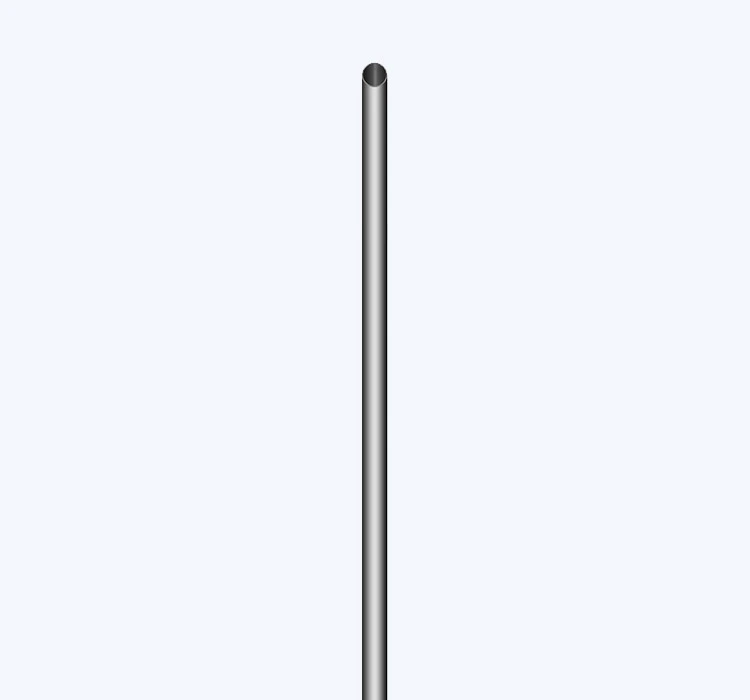

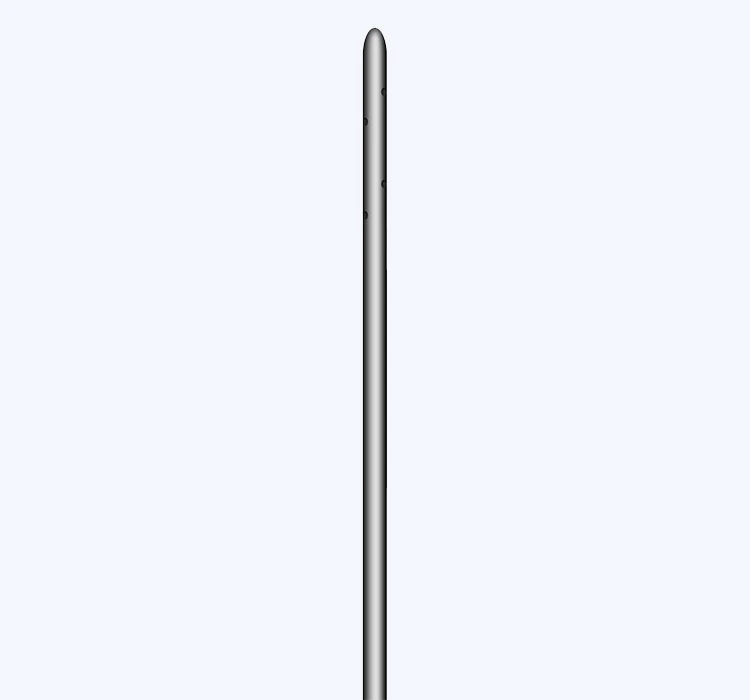

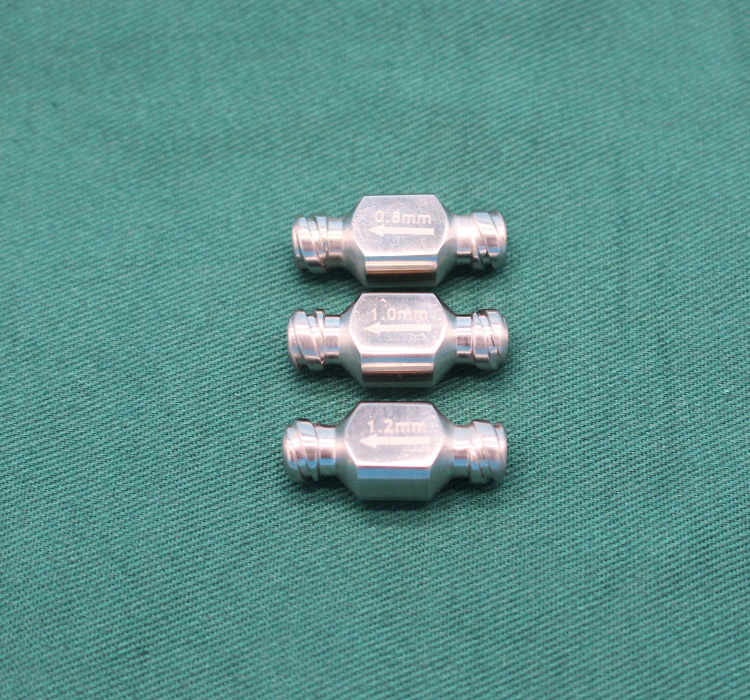

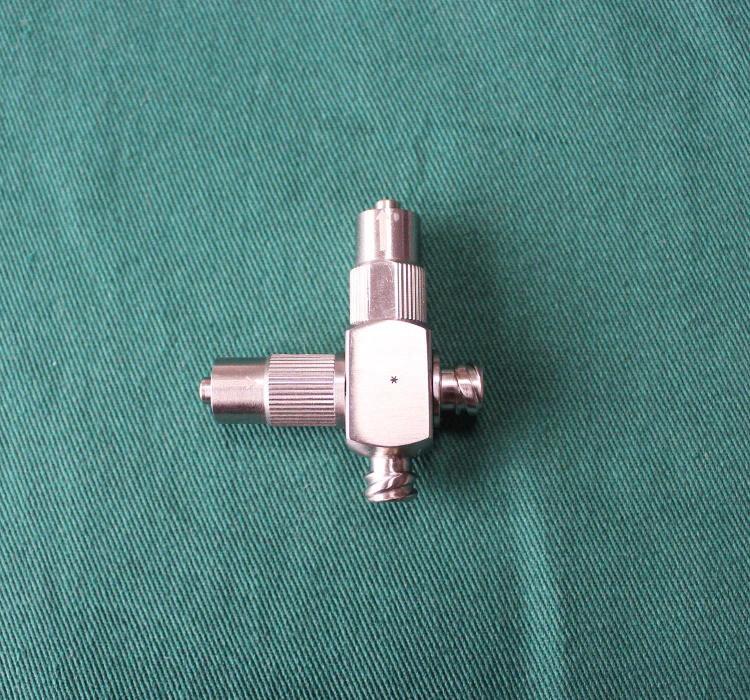

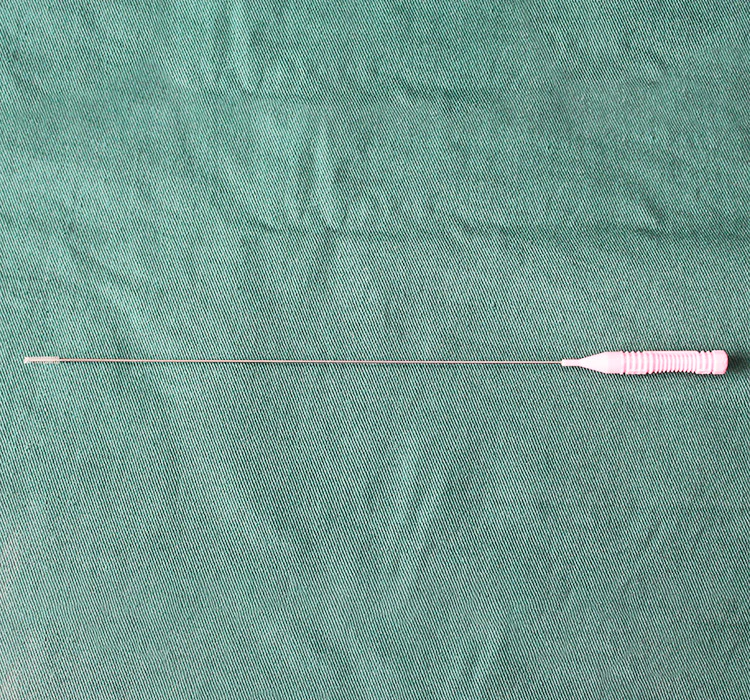

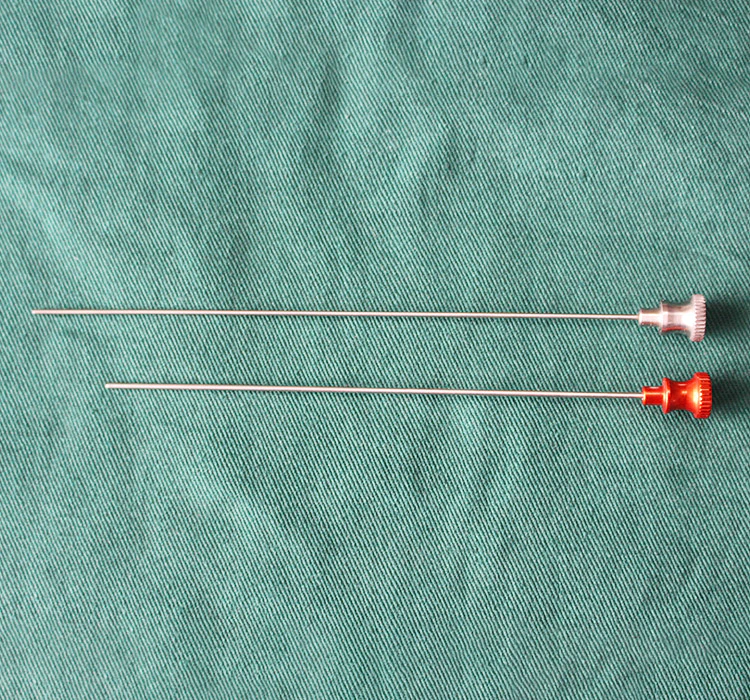

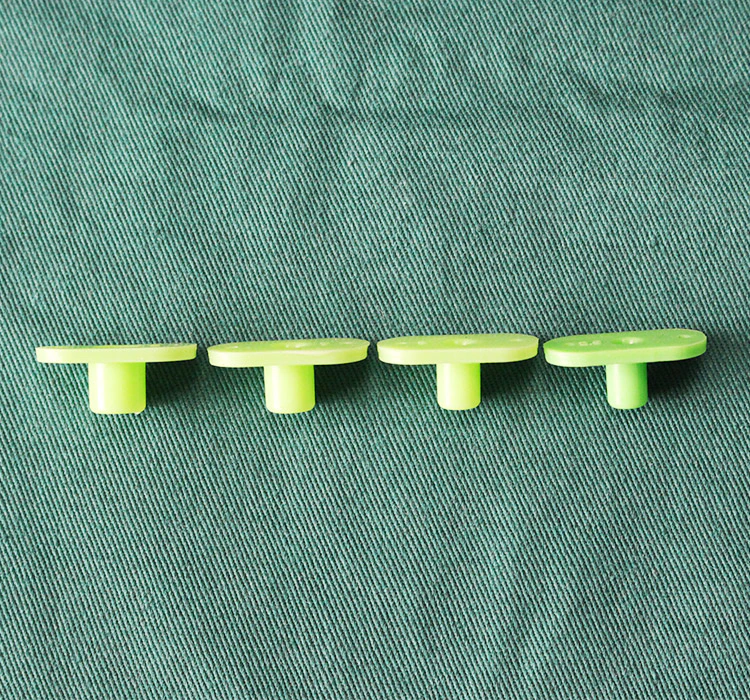

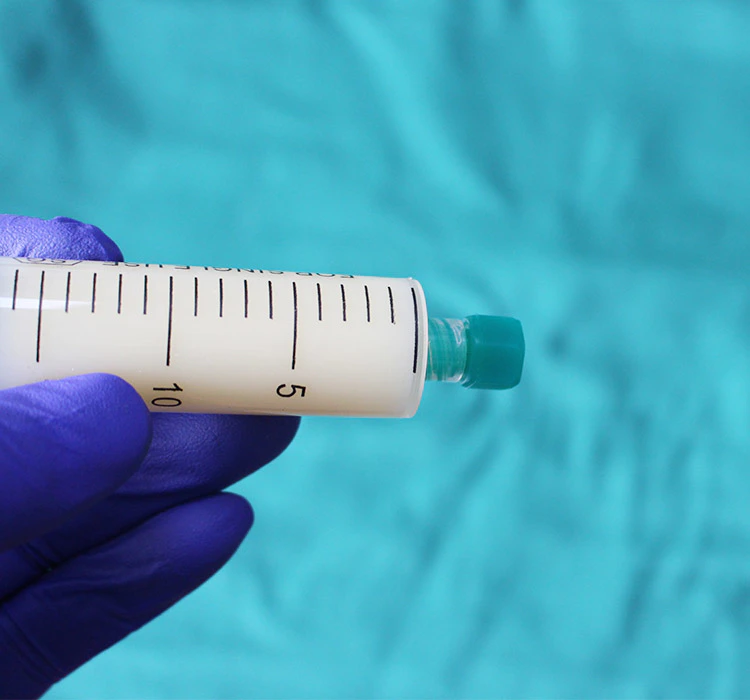

The production of liposuction cannulas requires a great deal of commitment, endurance, and of course, orderly manufacturing process. A complete and highly efficient production process can't be achieved without the combined efforts of staff. It starts with raw materials selection, then raw materials processing, appearance designing, semi-finished products processing, and end-products processing. In addition, the quality inspection process goes throughout the whole process to ensure a high qualification ratio. Different manufacturers may adopt different production methods but the results are almost the same - the products are guaranteed to be high-quality.

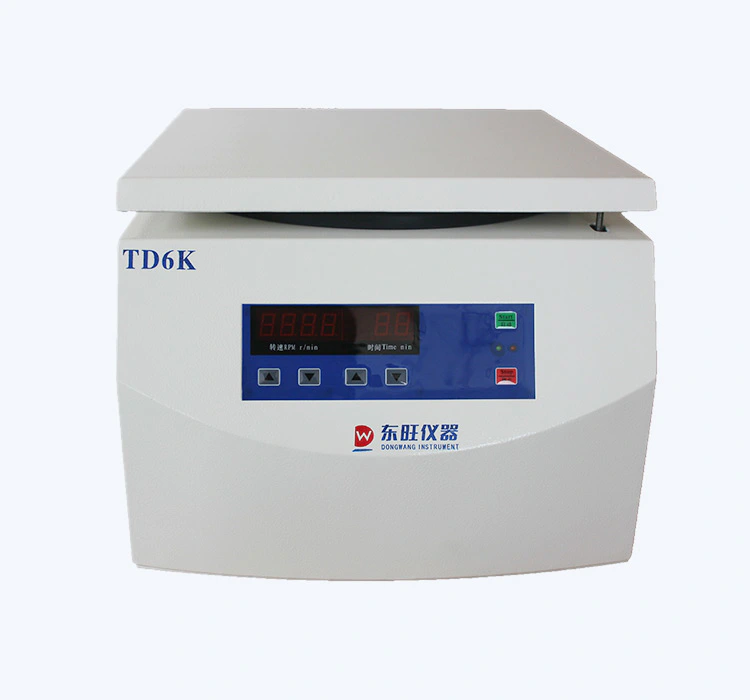

As an international company, Hangzhou Dino Medical Instruments Co., Ltd. has strong manufacturing foundation and solid expertise in centrifuge machine development and production. The accessory instruments series has become a hot product of Dino Medical Instruments . Dino micro cannulas conforms to the CCC standard which requires that its life expectancy is no less than 10,000 hours. Besides, the product is up to the international LED lighting quality standards. The product can help remove fat cells permanently. The product has the advantage of water repellency. Its seam sealing and coating create a barrier to block the water. Due to its flexibility, the product will not cause discomfort to the patient.

We proactively conduct sustainable operations. For instance, we are constantly introducing advanced production technologies to reduce water waste and CO2 emissions.

As an international company, Hangzhou Dino Medical Instruments Co., Ltd. has strong manufacturing foundation and solid expertise in centrifuge machine development and production. The accessory instruments series has become a hot product of Dino Medical Instruments . Dino micro cannulas conforms to the CCC standard which requires that its life expectancy is no less than 10,000 hours. Besides, the product is up to the international LED lighting quality standards. The product can help remove fat cells permanently. The product has the advantage of water repellency. Its seam sealing and coating create a barrier to block the water. Due to its flexibility, the product will not cause discomfort to the patient.

We proactively conduct sustainable operations. For instance, we are constantly introducing advanced production technologies to reduce water waste and CO2 emissions.

Custom message

Español

Español

Sales Manager : Kelly Zhou

Sales Manager : Kelly Zhou Email :

Email :  WhatsApp : +86 18067965386

WhatsApp : +86 18067965386