How did Dino Medical Instruments design infiltration cannulas?

2021-01-16

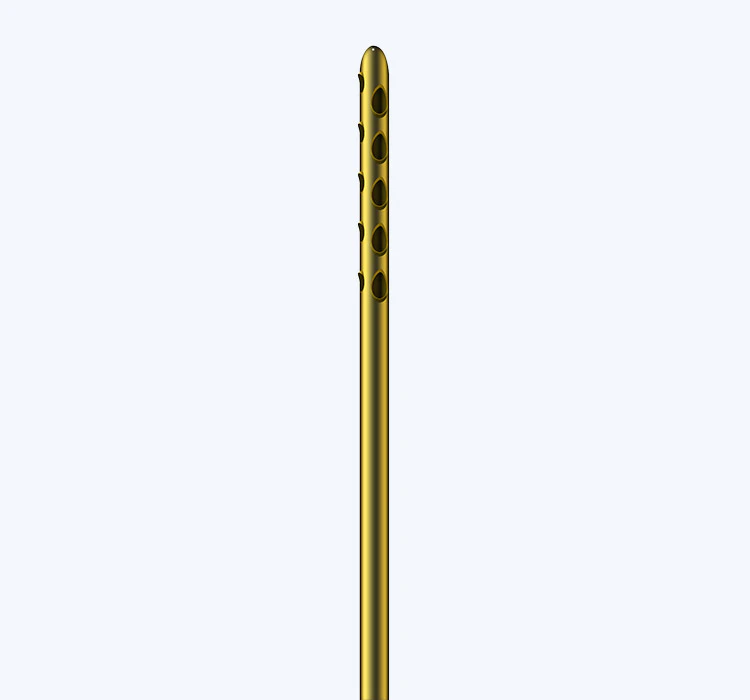

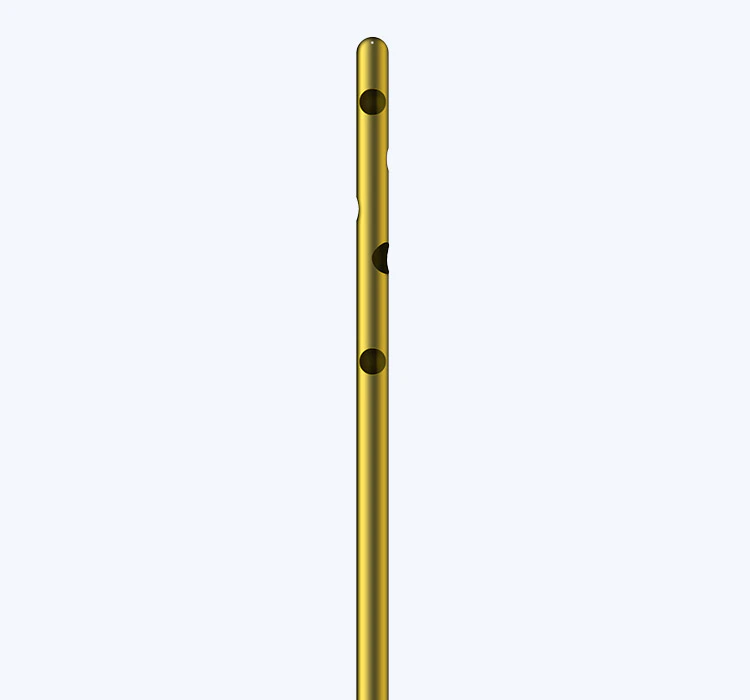

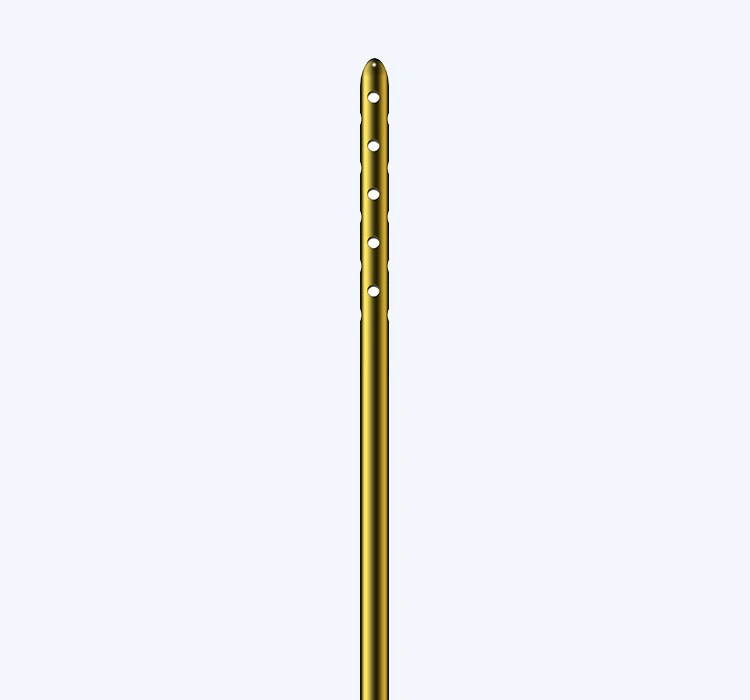

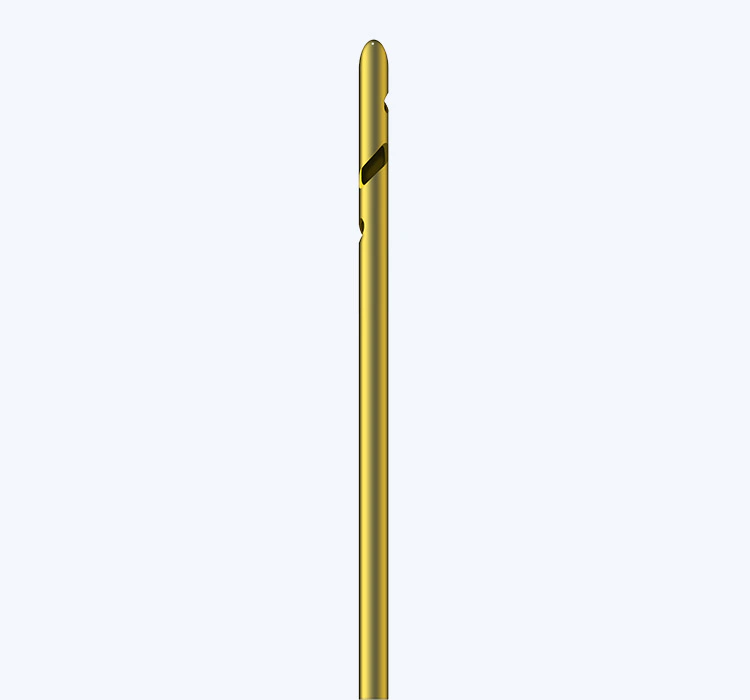

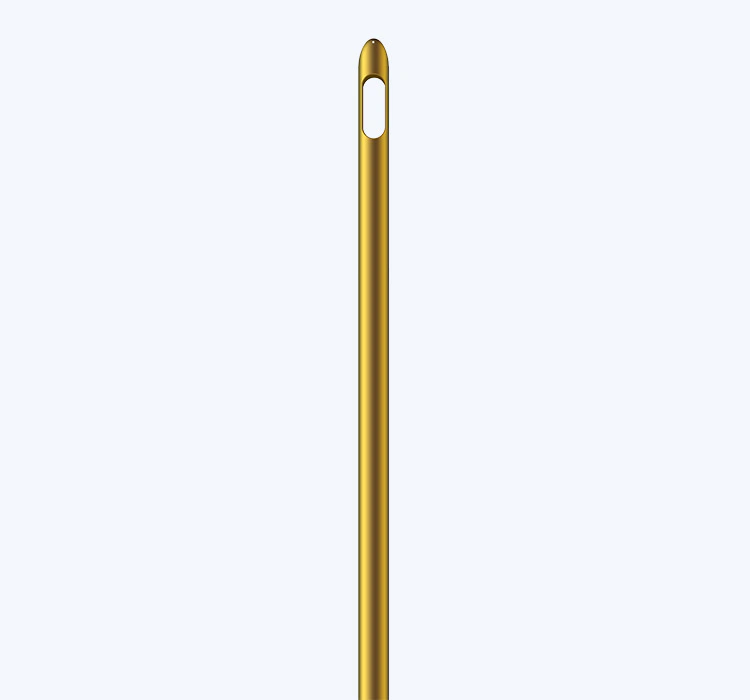

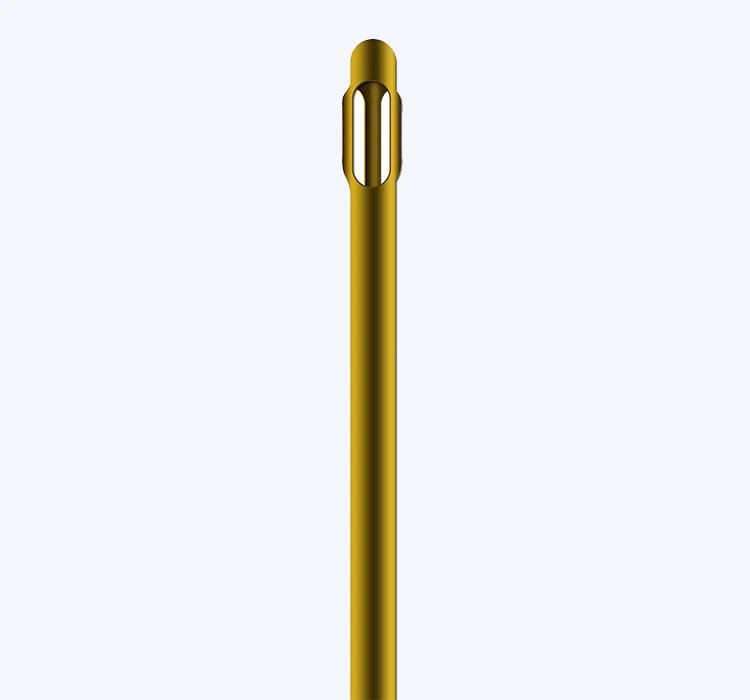

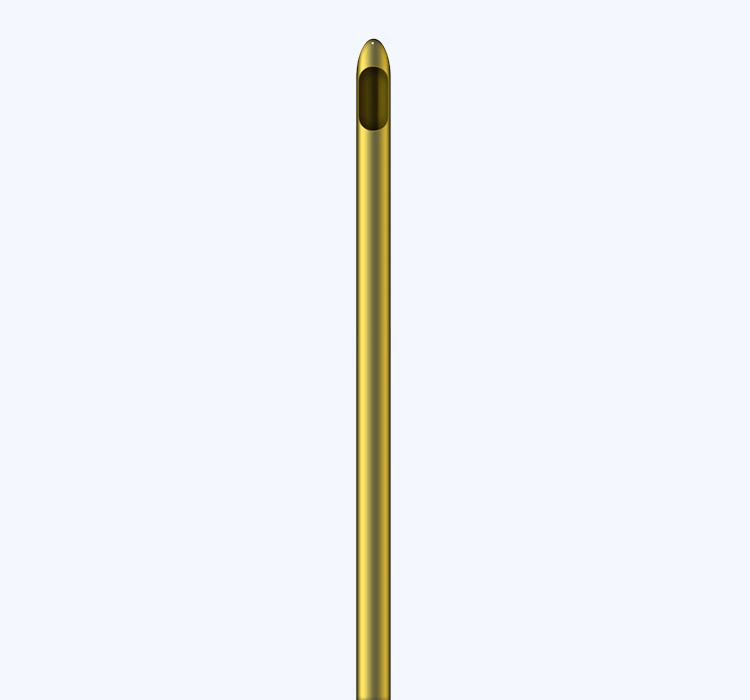

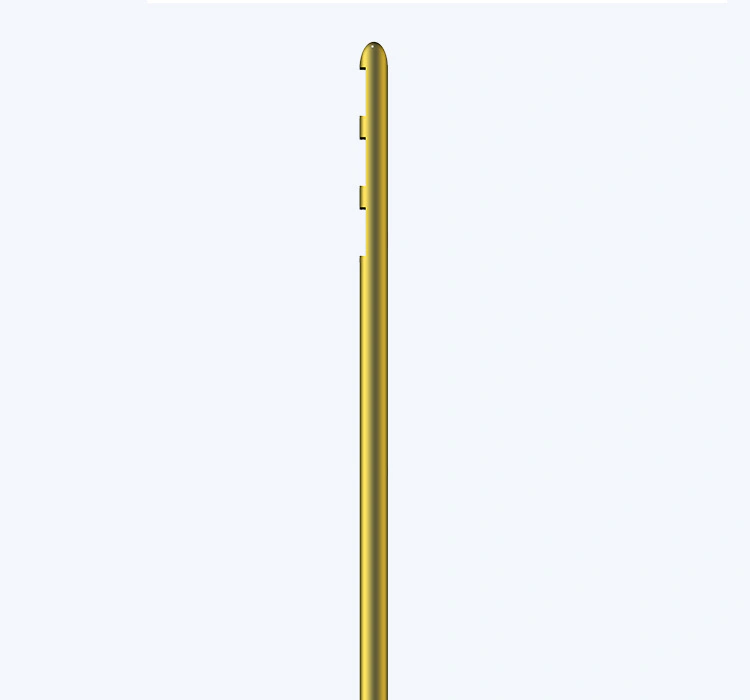

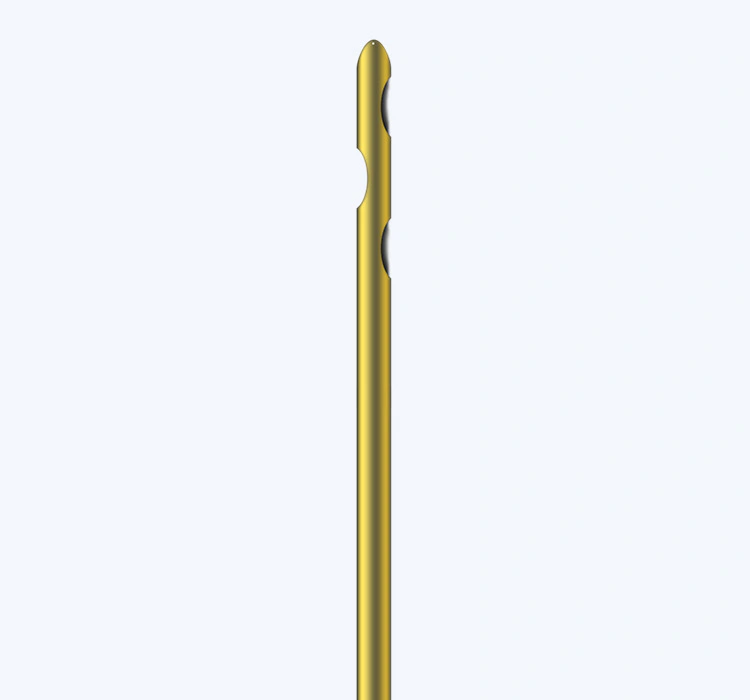

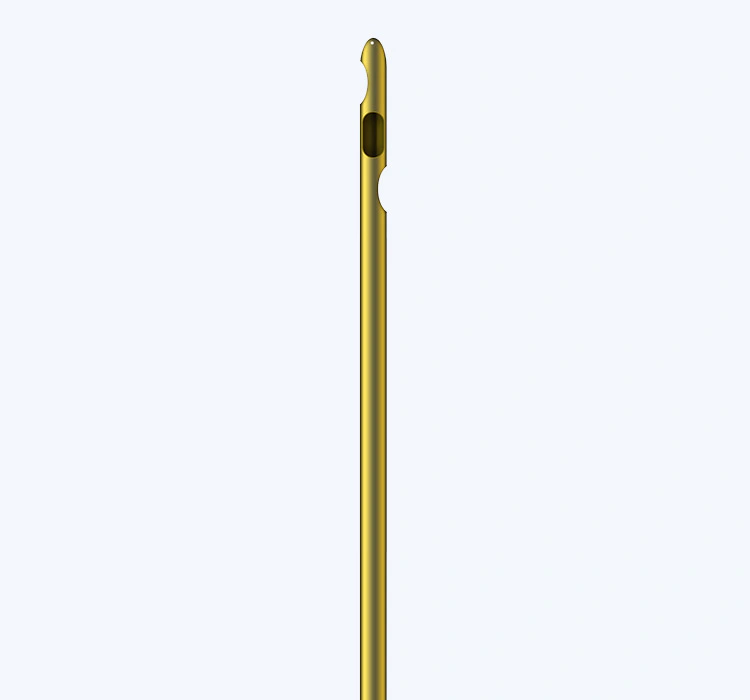

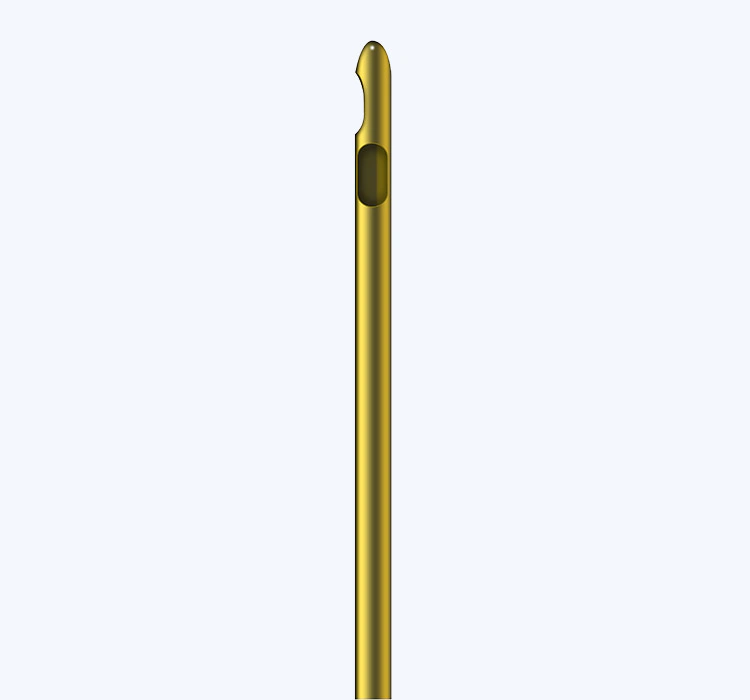

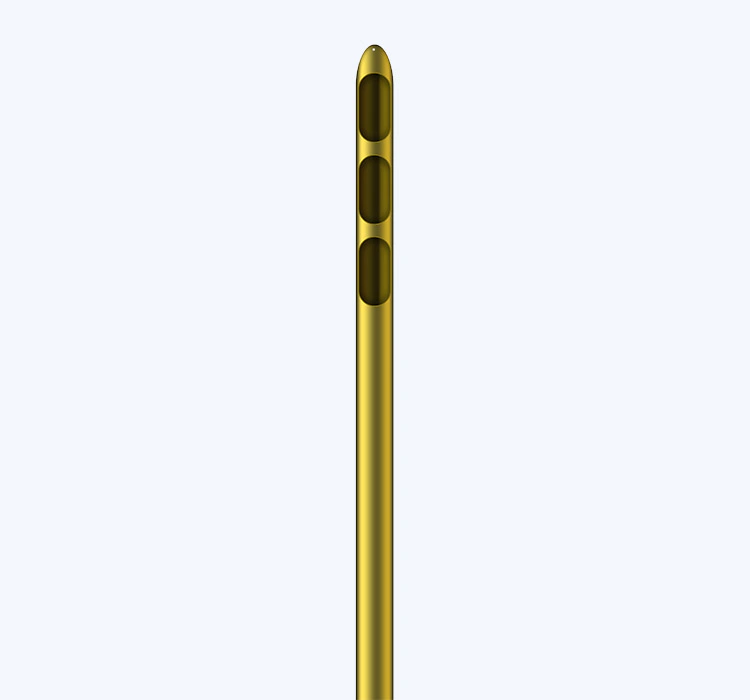

At Hangzhou Dino Medical Instruments Co., Ltd., the design process of infiltration cannulas has several stages and steps, and each of them can be methodized and be done regularly. Typically, there are 4 steps for us to carry out the design procedure. Firstly, we start with gathering the necessary information and requirements from customers. This is usually achieved by either a face-to-face meeting with the client, a questionnaire (on- or off-line), or even a Skype meeting. Secondly, this step is mainly focusing on design creation. Having got in-depth research of customers and their products, target market and competitors, we will begin brainstorming to decide the colors, shapes, and other elements. The next step is evaluating the design work and doing the refinement if possible. Customers should provide any feedback they may have once seeing the design. The last step is to apply the confirmed design work into the production formally.

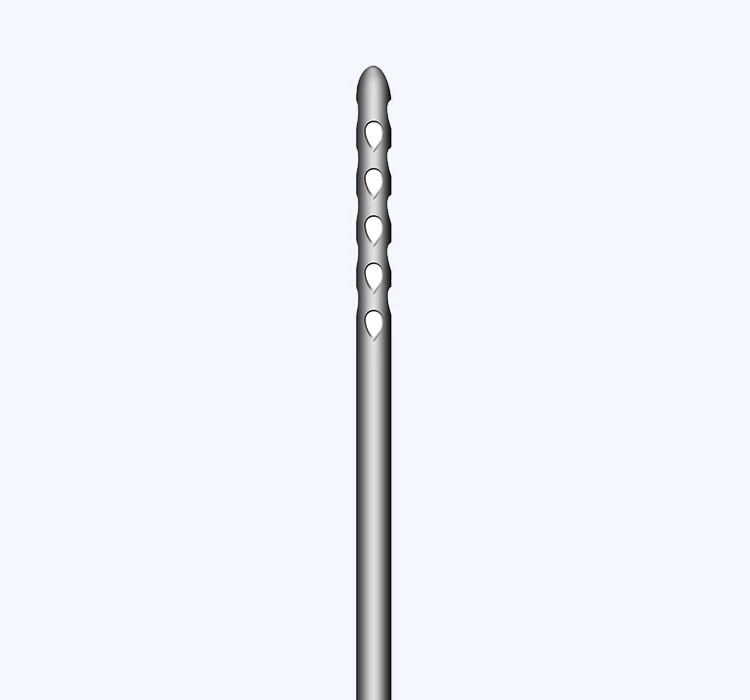

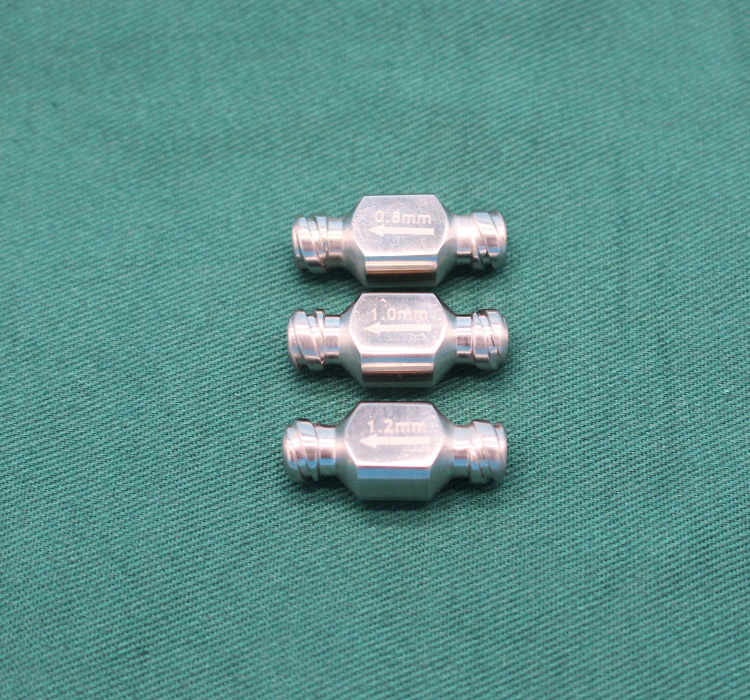

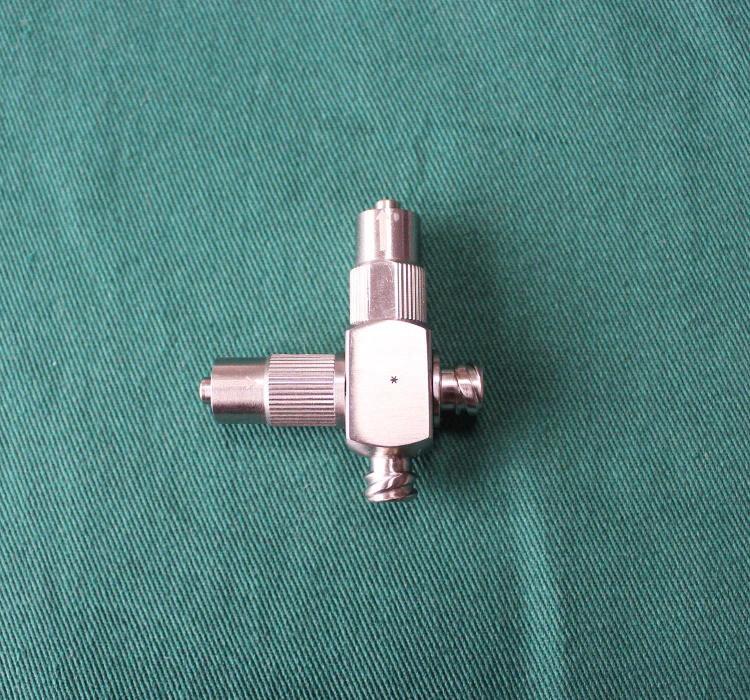

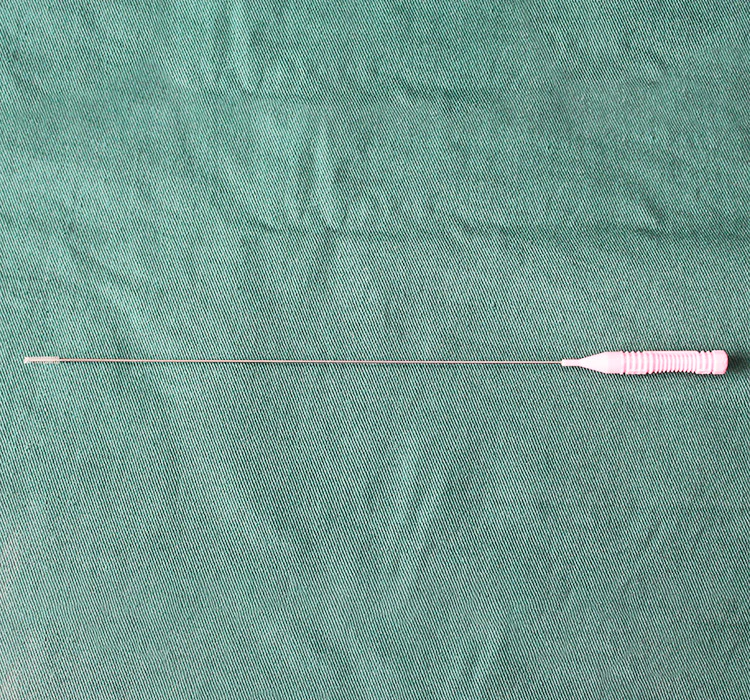

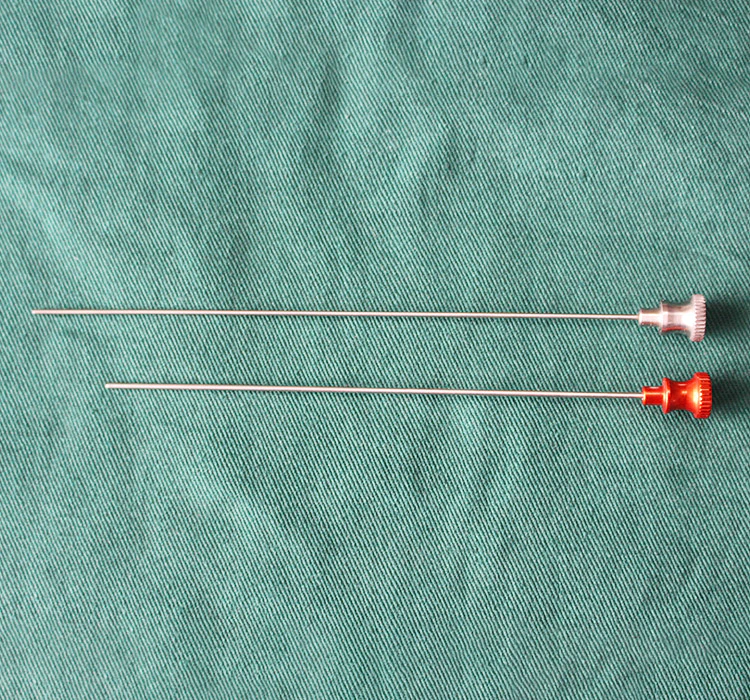

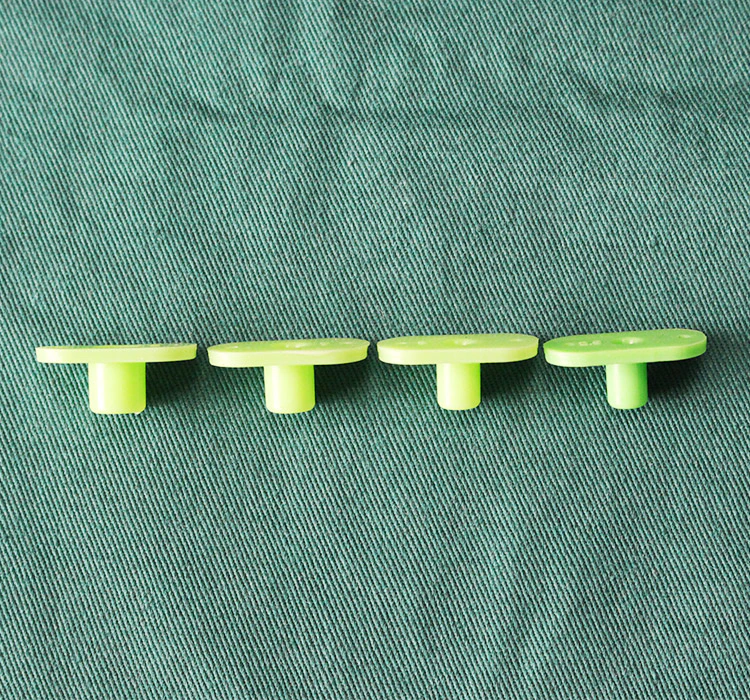

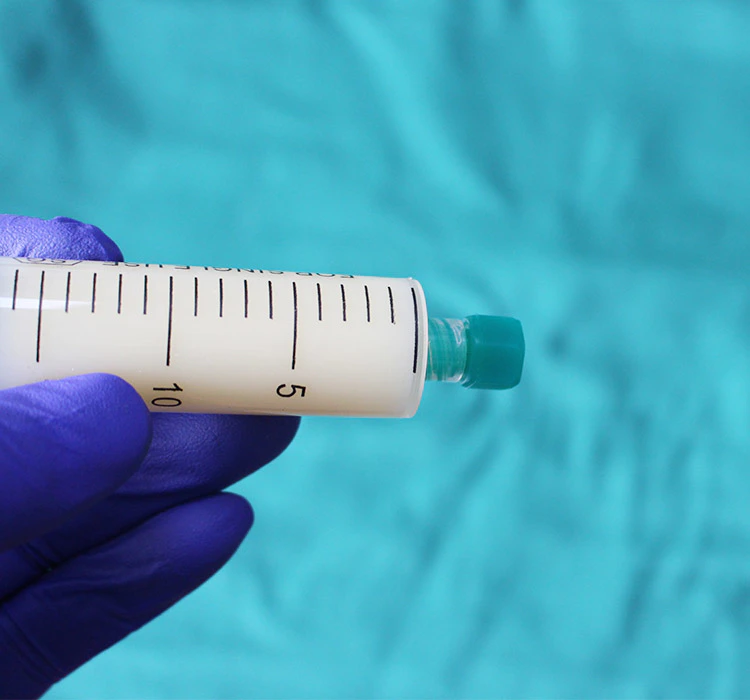

The constant development of Dino promotes its position in nano fat grafting cannula industry. According to the material, Dino Medical Instruments 's products are divided into several categories, and syringe cap is one of them. Dino Medical Instruments 's raw materials actively comply with international green specifications and customer requirements. Thanks to its tissue-friendly design, the product can decrease postoperative pain, ecchymoses, and edema. The product has excellent performance and stable quality. Processed by CNC machines, the product features high precision with no flaws.

Dino Medical Instruments is committed to build a well-known brand in infiltration cannula industry. Inquire!

The constant development of Dino promotes its position in nano fat grafting cannula industry. According to the material, Dino Medical Instruments 's products are divided into several categories, and syringe cap is one of them. Dino Medical Instruments 's raw materials actively comply with international green specifications and customer requirements. Thanks to its tissue-friendly design, the product can decrease postoperative pain, ecchymoses, and edema. The product has excellent performance and stable quality. Processed by CNC machines, the product features high precision with no flaws.

Dino Medical Instruments is committed to build a well-known brand in infiltration cannula industry. Inquire!

Custom message

Español

Español

Sales Manager : Kelly Zhou

Sales Manager : Kelly Zhou Email :

Email :  WhatsApp : +86 18067965386

WhatsApp : +86 18067965386