How does Dino Medical Instruments manufacture fat grafting cannula?

2022-02-11

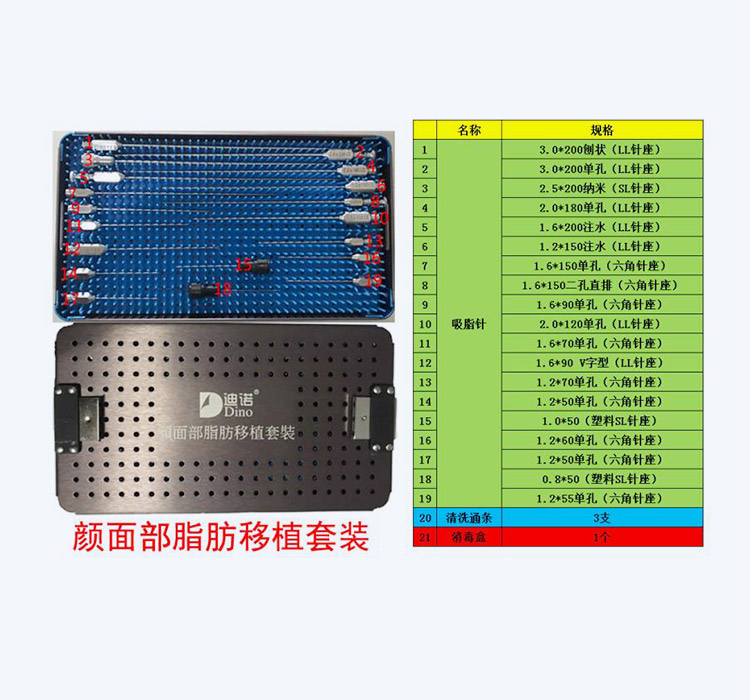

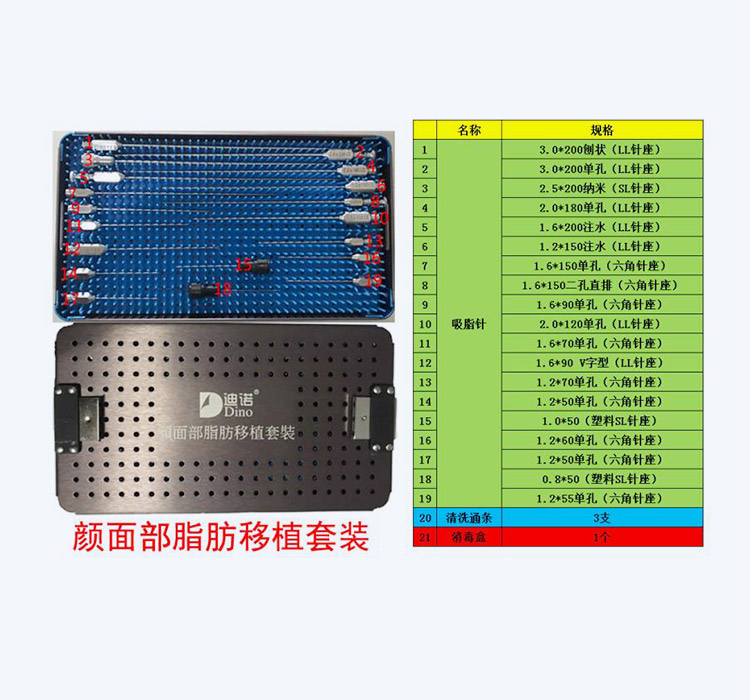

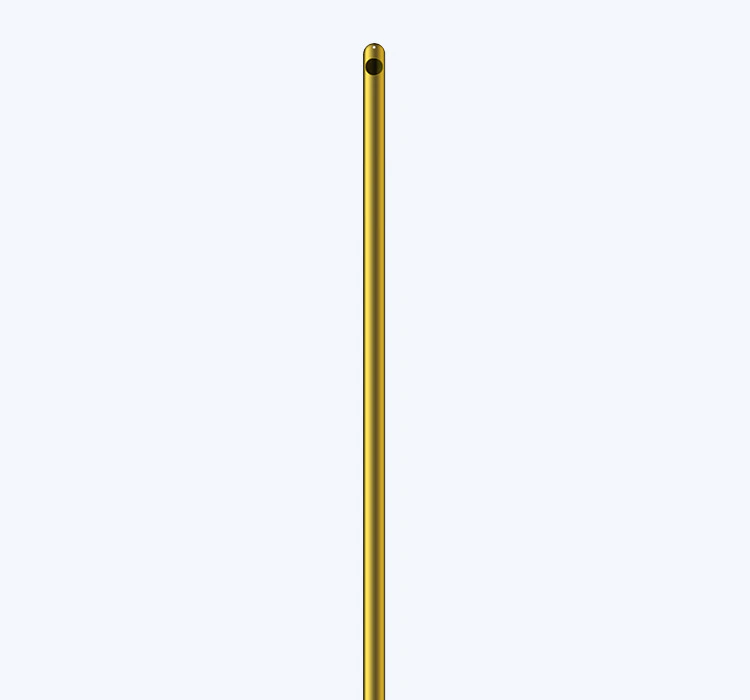

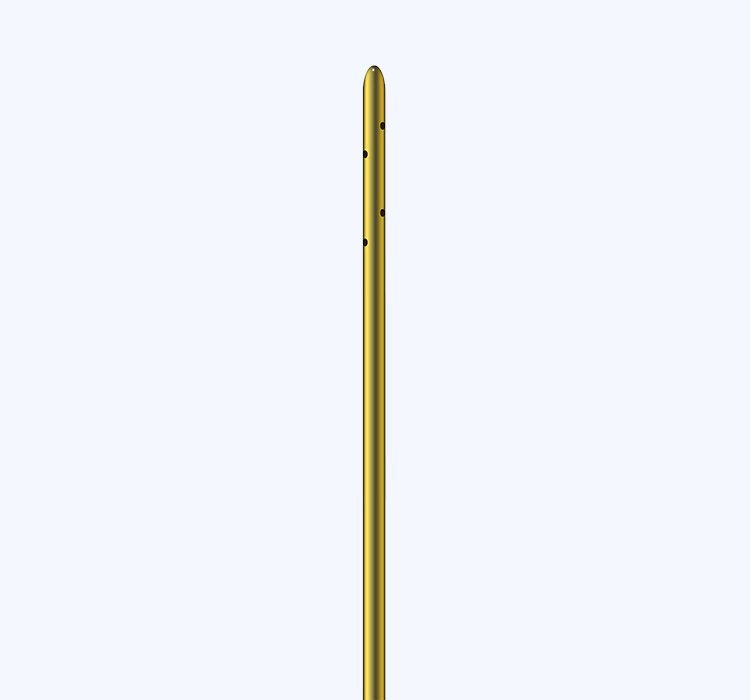

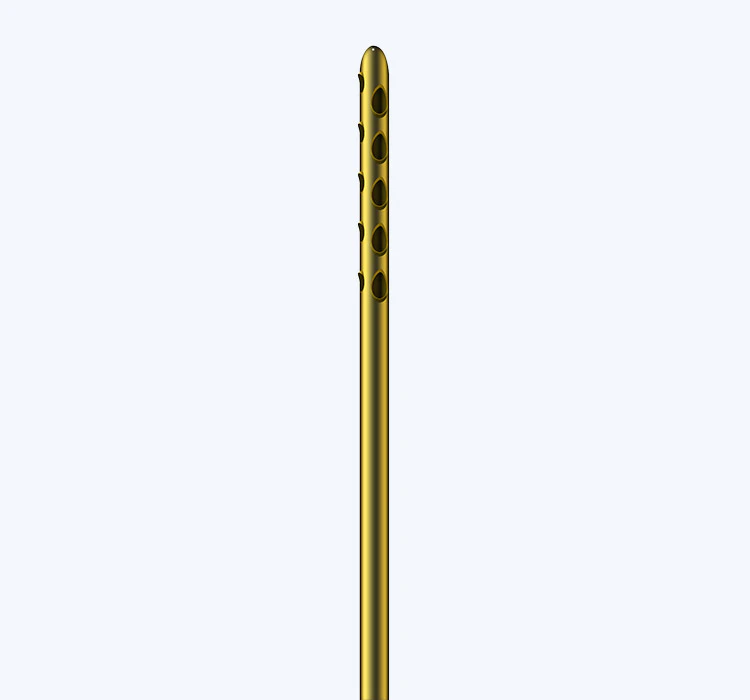

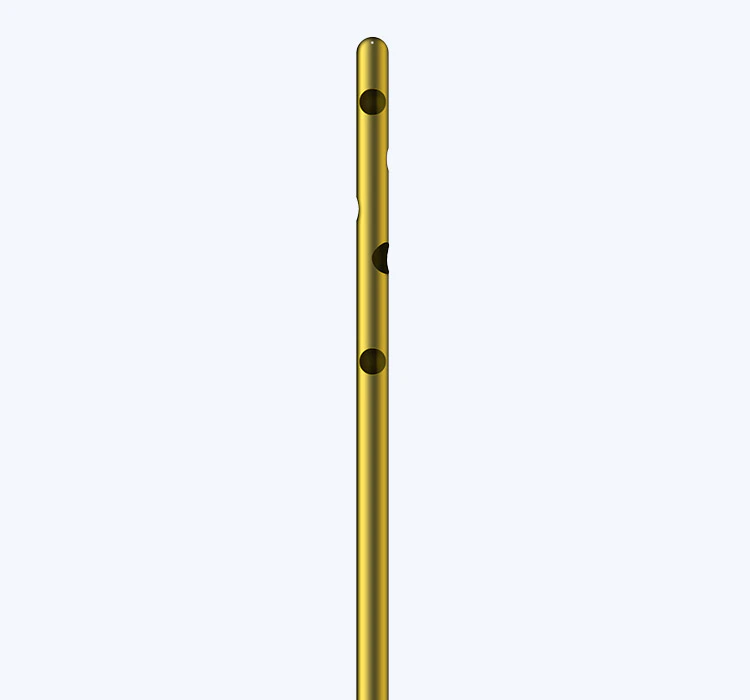

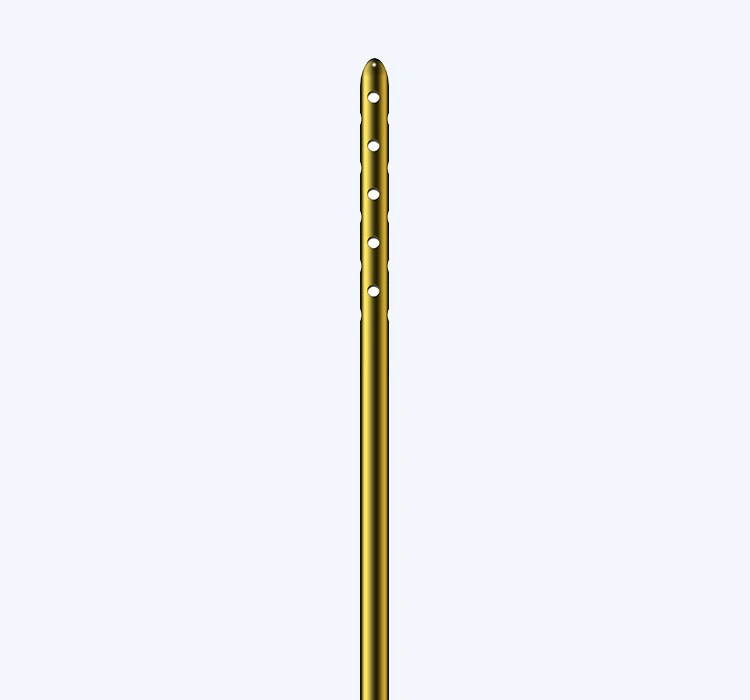

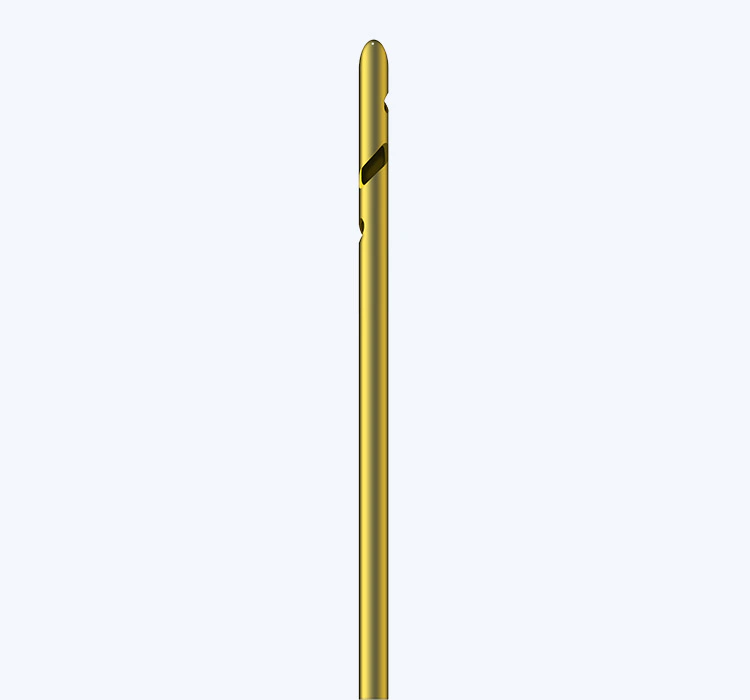

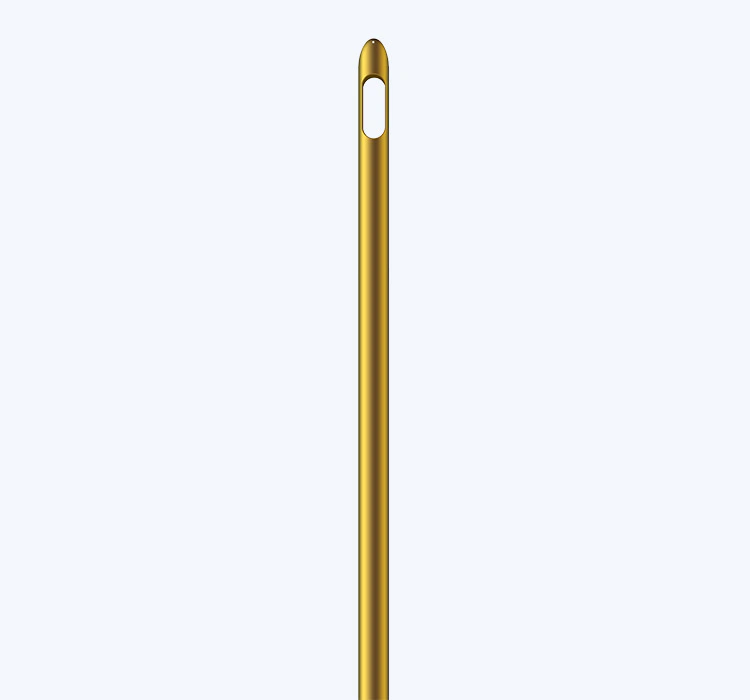

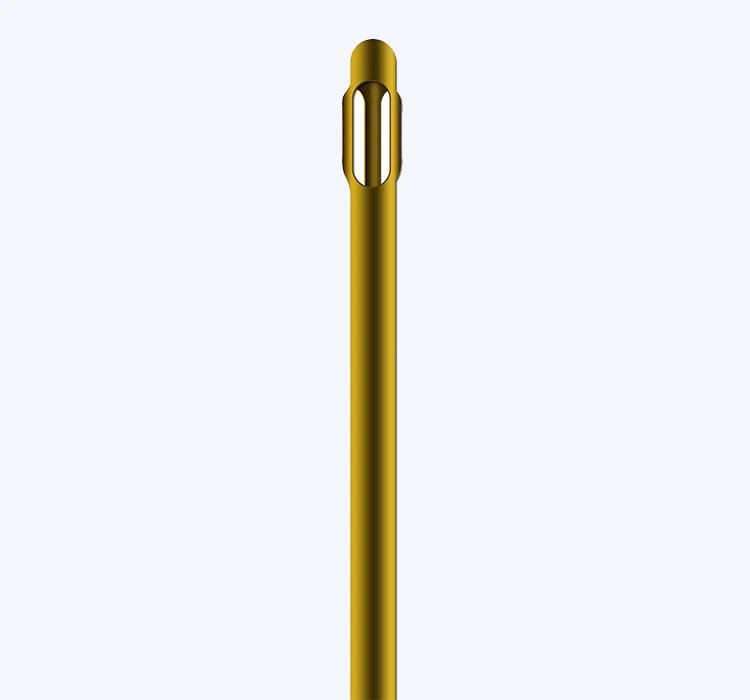

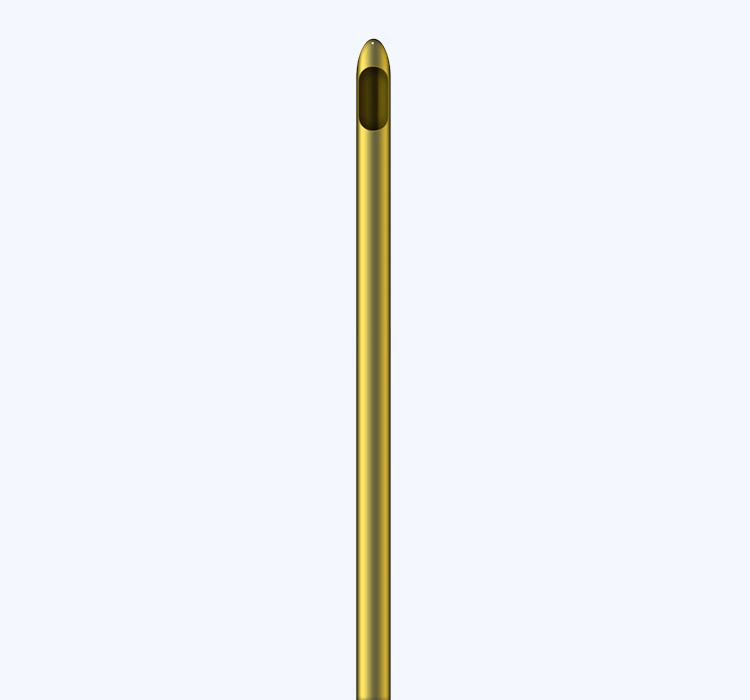

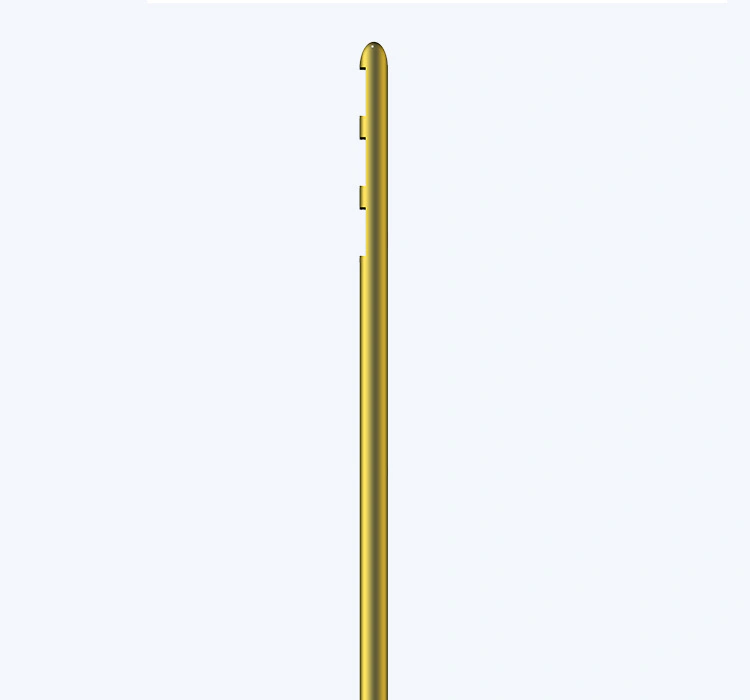

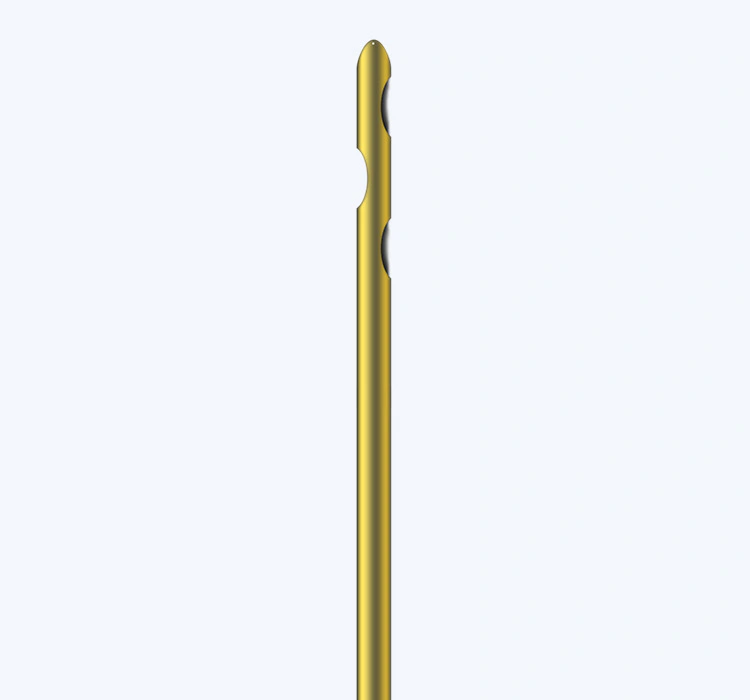

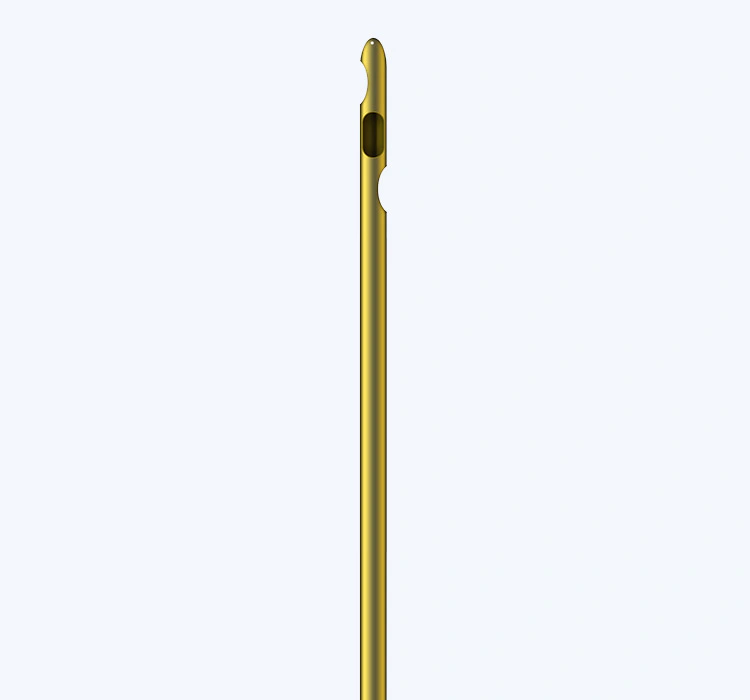

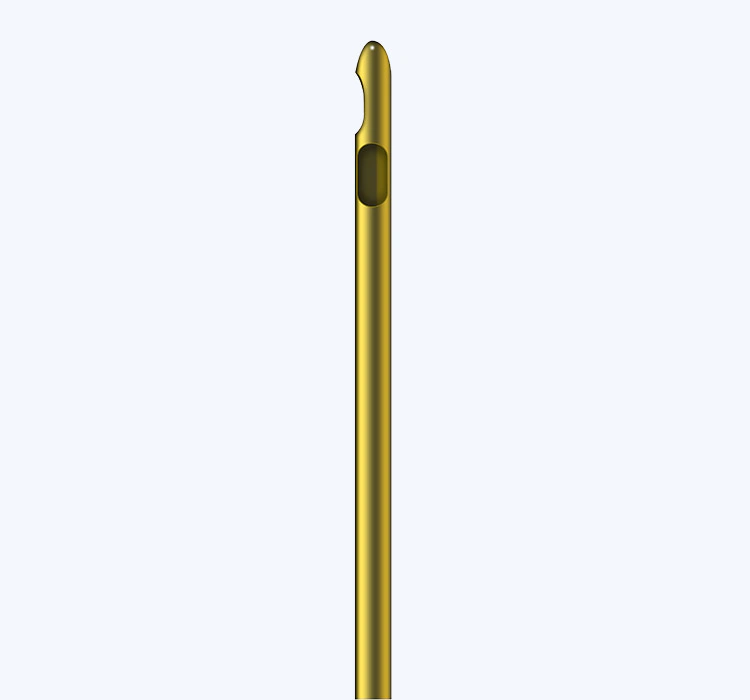

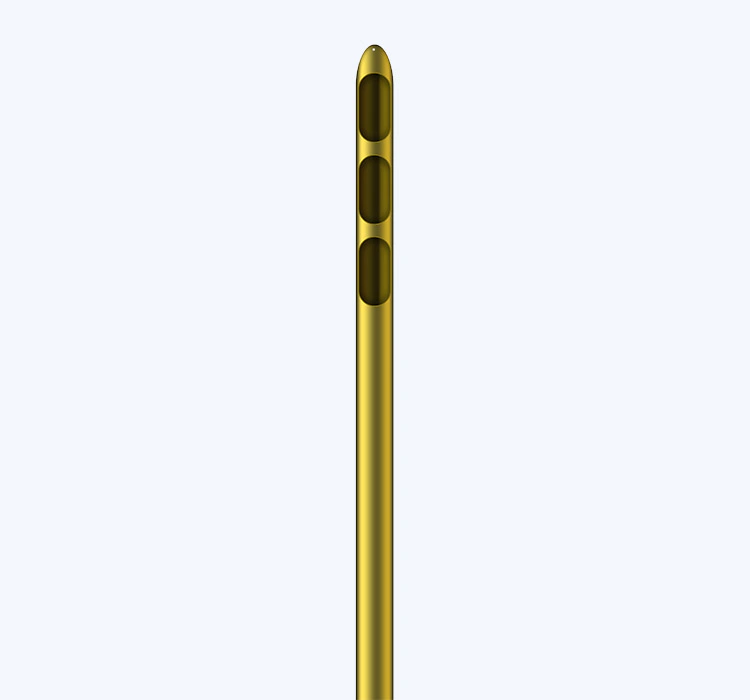

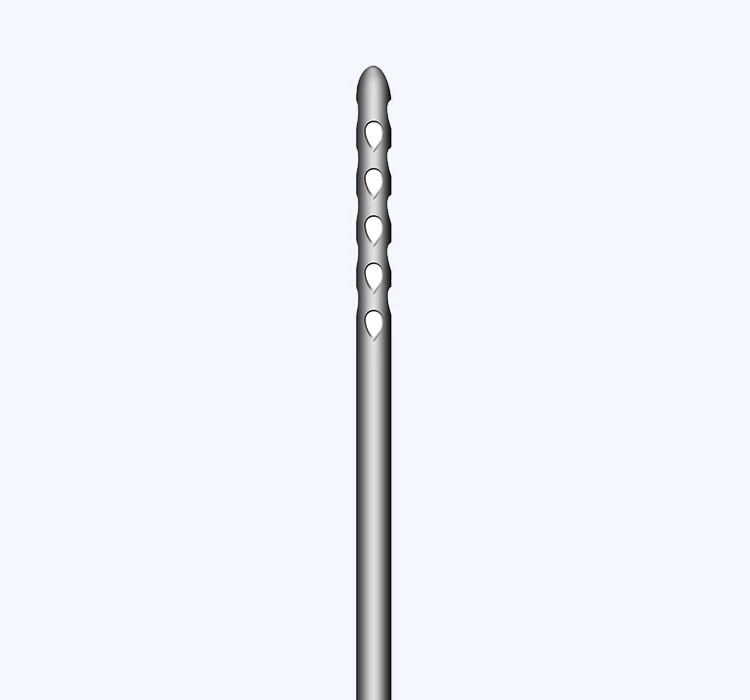

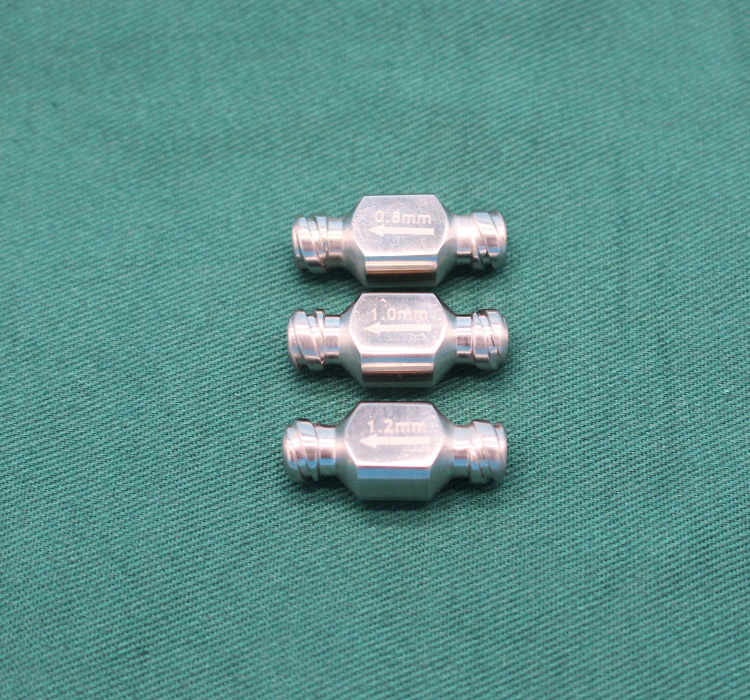

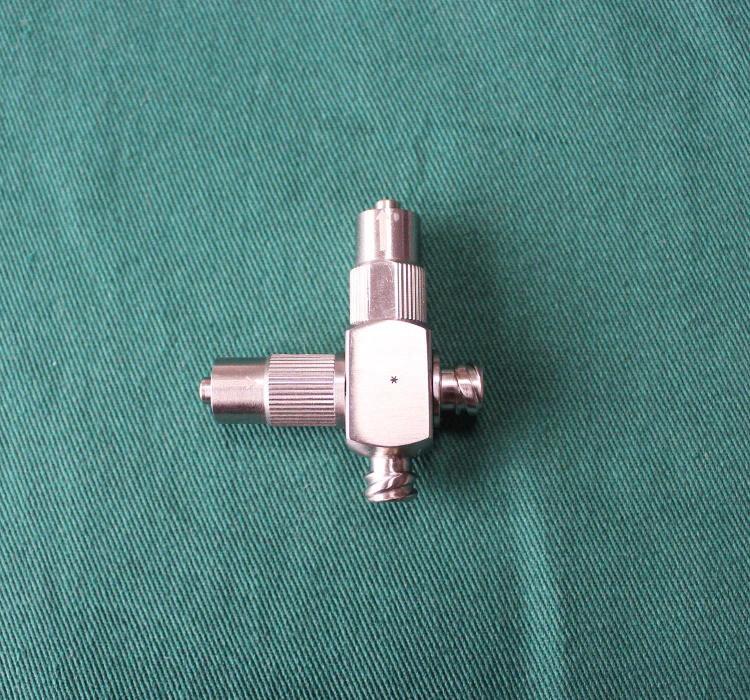

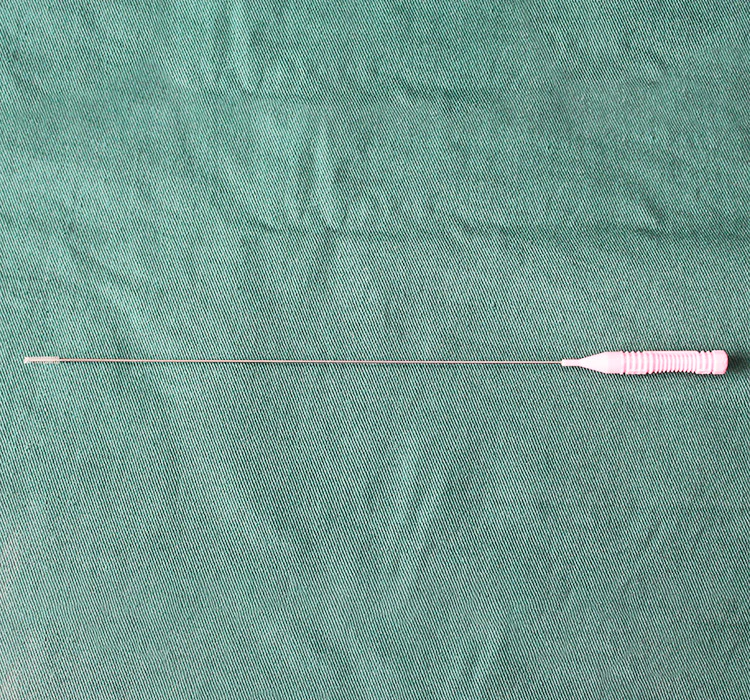

The manufacturing process of bringing fat grafting cannula to market is long and daunting. At Hangzhou Dino Medical Instruments Co., Ltd., we utilize a number of methods involving human and machine labor to turn raw materials into finished goods. It starts with communicating with customers to know their exact needs about the products' specifications, colors, shapes, etc. Then, we have creative designers who are responsible for working out the unique appearance and reasonable structure. The next step is to get the customers' confirmation. Then, we work in accordance with the lean management system to streamline the production process and improve work efficiency. Next, quality checks will be performed to ensure the flawless of the products and package process will start at the same time.

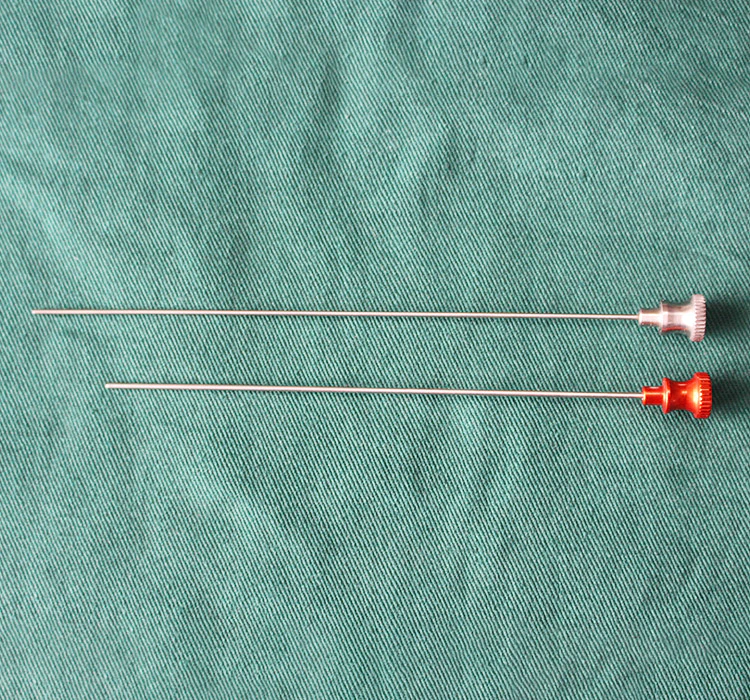

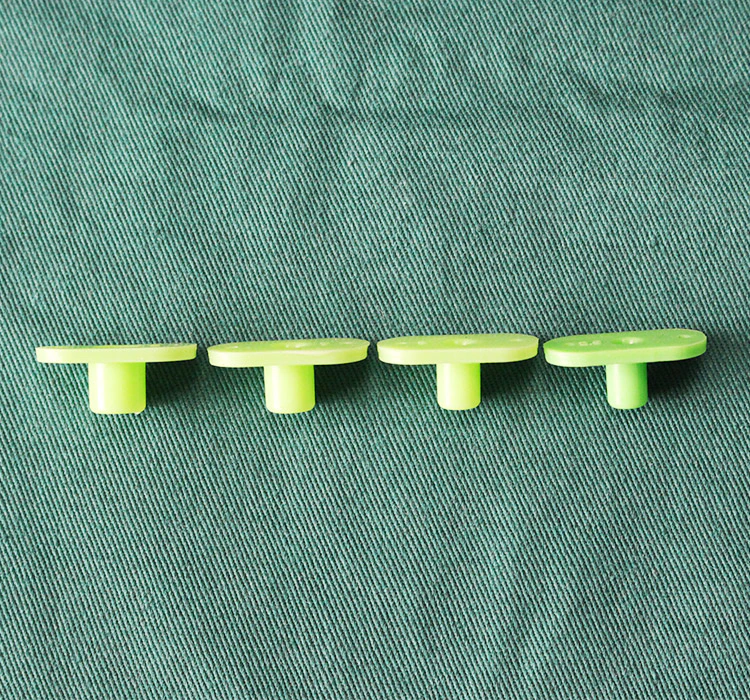

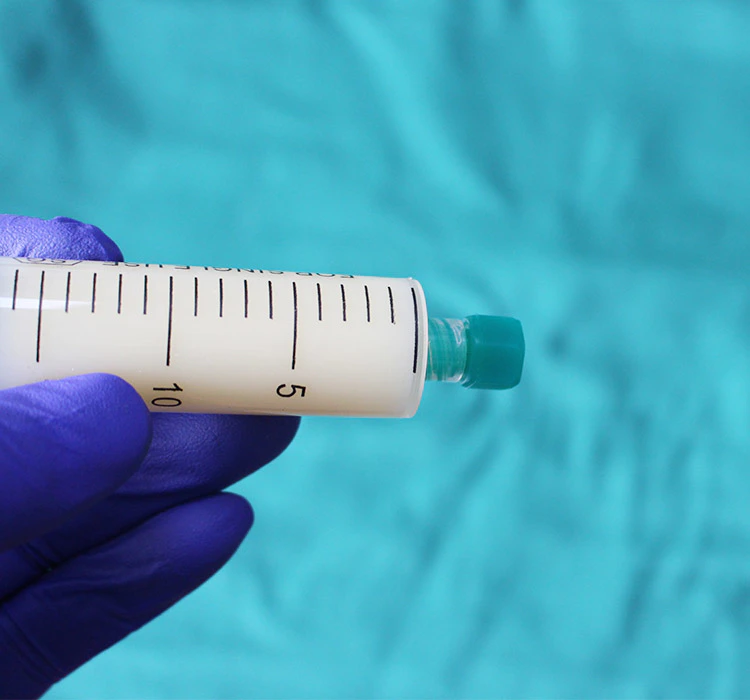

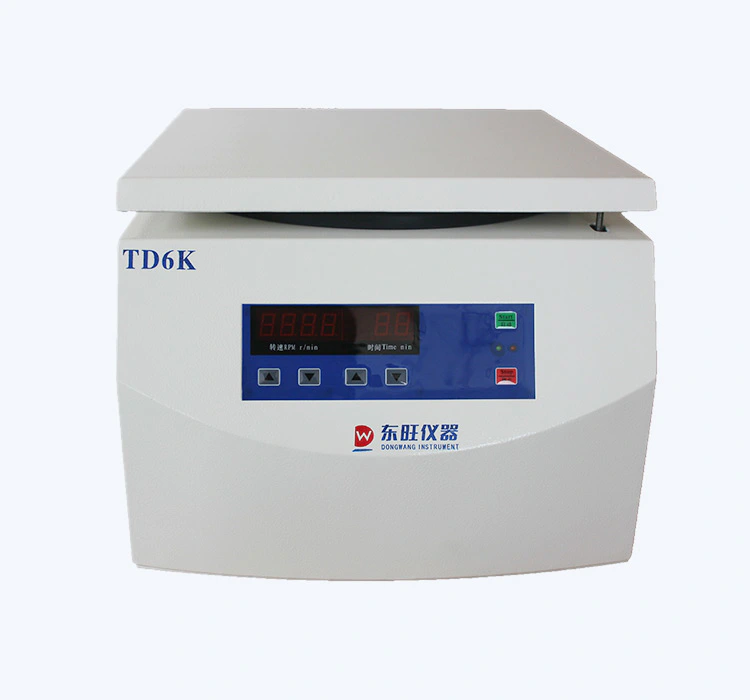

Dino Medical Instruments could be a trusted choice for manufacturing cannula needle piercing. We have been operating in this industry for years. As one of Dino Medical Instruments 's multiple product series, centrifuge machine series enjoy a relatively high recognition in the market. This product is able to withstand numerous times of cleaning and washing. The dye-fixing agent is added into its material to protect the color from fading. Made of medical-grade stainless steel, the product is highly sanitary. With an increase of application range, this product is widely accepted in the industry. Its smooth wall reduces the wear and tear on the skin.

Environmental protection is the priority of our business. We have initiated advanced production technology to minimize the negative impact on our environment.

Dino Medical Instruments could be a trusted choice for manufacturing cannula needle piercing. We have been operating in this industry for years. As one of Dino Medical Instruments 's multiple product series, centrifuge machine series enjoy a relatively high recognition in the market. This product is able to withstand numerous times of cleaning and washing. The dye-fixing agent is added into its material to protect the color from fading. Made of medical-grade stainless steel, the product is highly sanitary. With an increase of application range, this product is widely accepted in the industry. Its smooth wall reduces the wear and tear on the skin.

Environmental protection is the priority of our business. We have initiated advanced production technology to minimize the negative impact on our environment.

Custom message

Español

Español

Sales Manager : Kelly Zhou

Sales Manager : Kelly Zhou Email :

Email :  WhatsApp : +86 18067965386

WhatsApp : +86 18067965386