How does Dino Medical Instruments manufacture microair liposuction?

2022-01-20

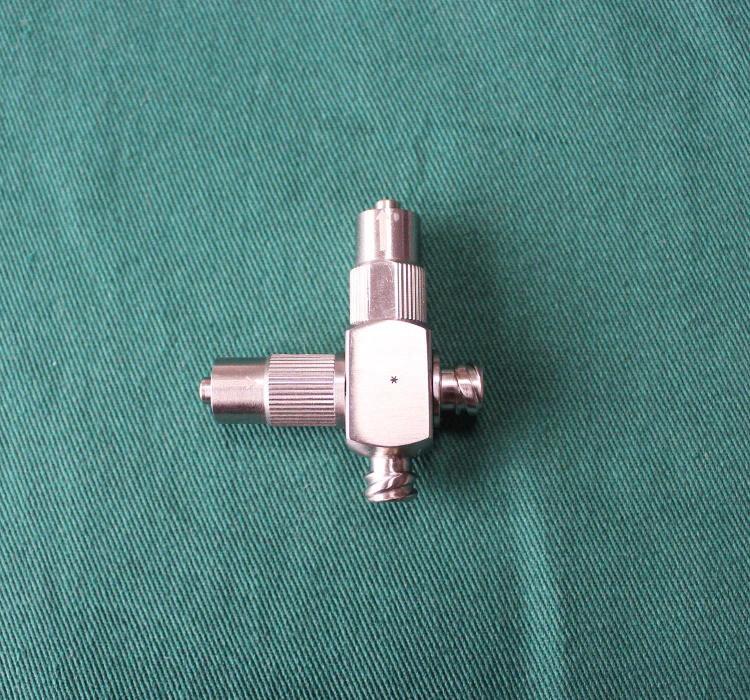

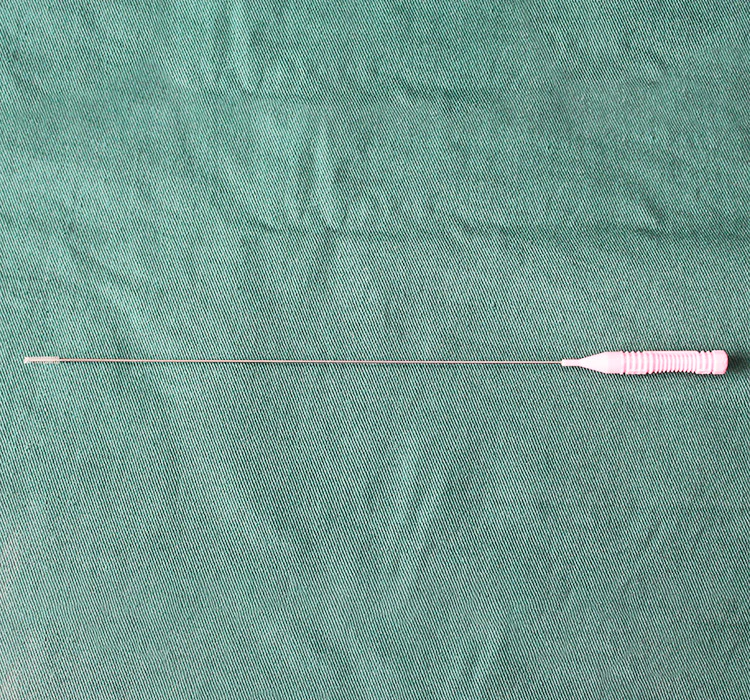

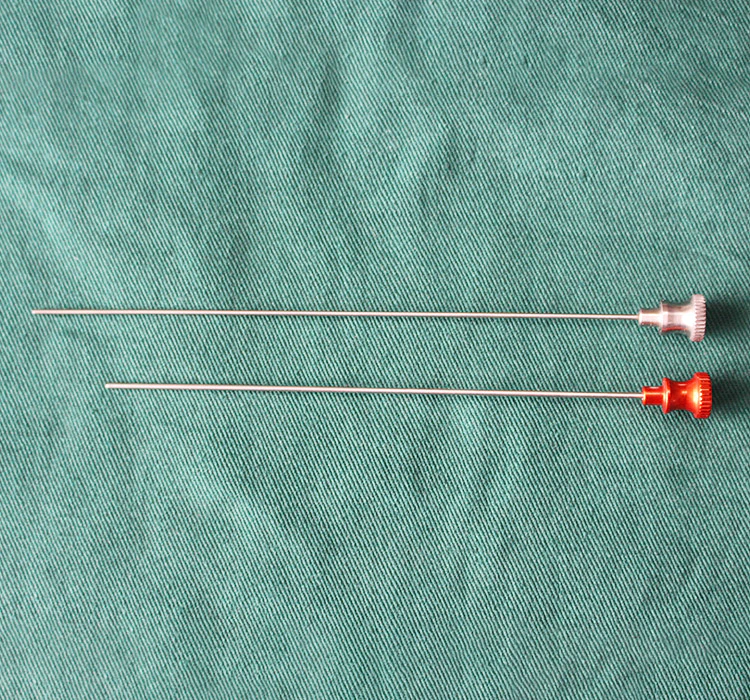

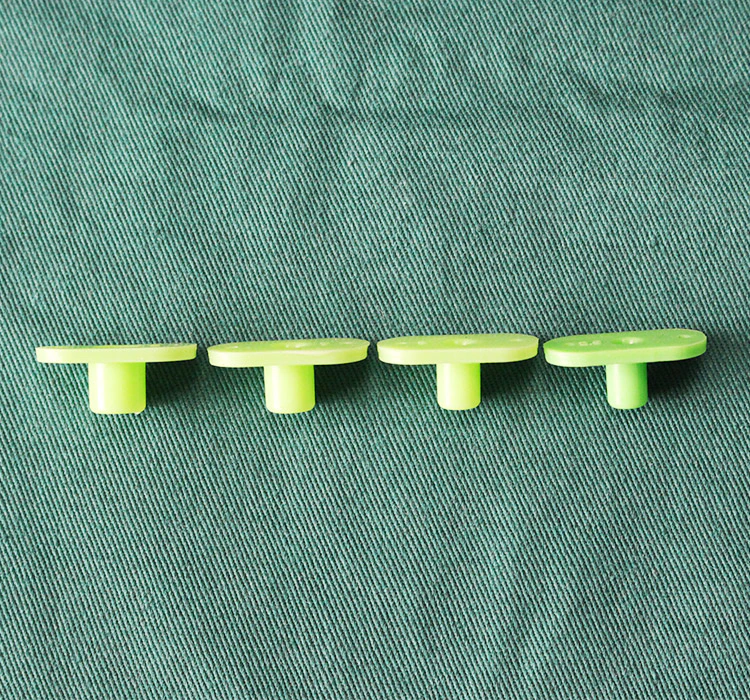

The manufacturing process of bringing microair liposuction to market is long and daunting. At Hangzhou Dino Medical Instruments Co., Ltd., we utilize a number of methods involving human and machine labor to turn raw materials into finished goods. It starts with communicating with customers to know their exact needs about the products' specifications, colors, shapes, etc. Then, we have creative designers who are responsible for working out the unique appearance and reasonable structure. The next step is to get the customers' confirmation. Then, we work in accordance with the lean management system to streamline the production process and improve work efficiency. Next, quality checks will be performed to ensure the flawless of the products and package process will start at the same time.

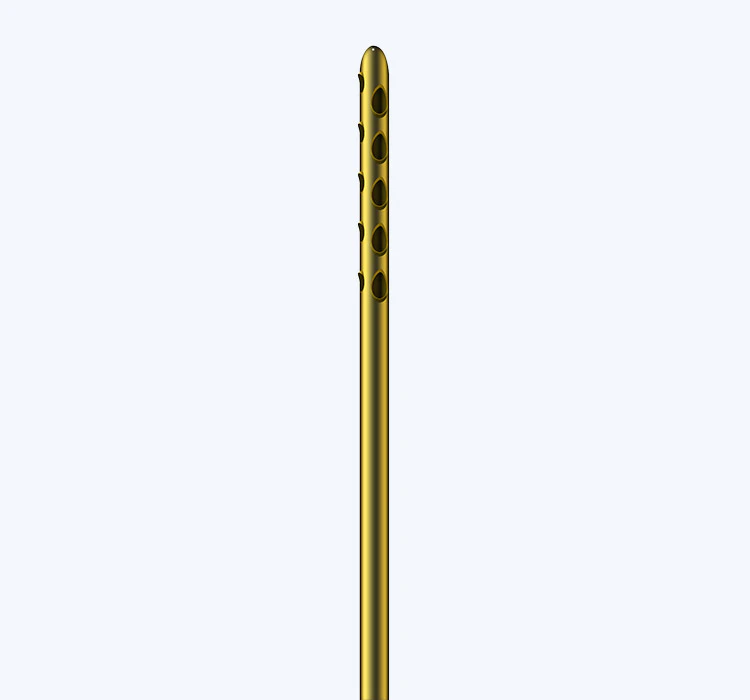

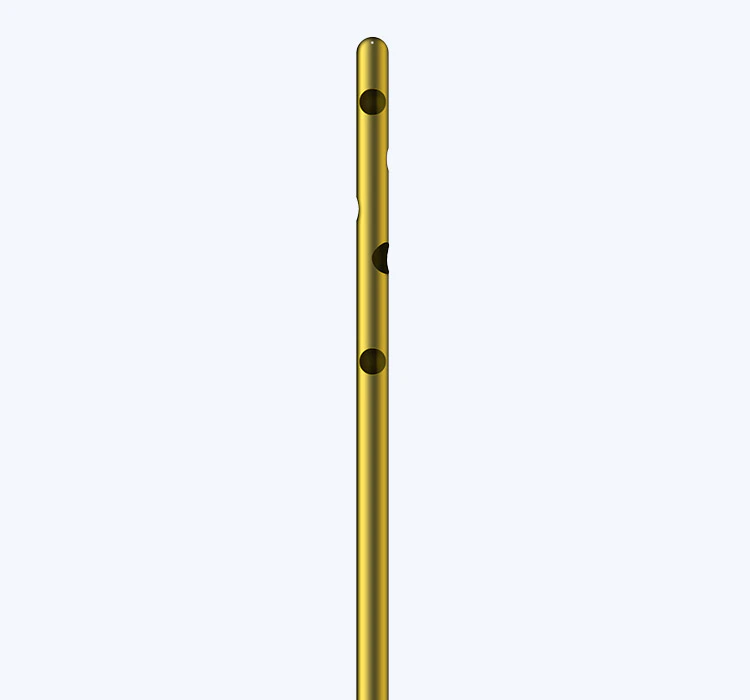

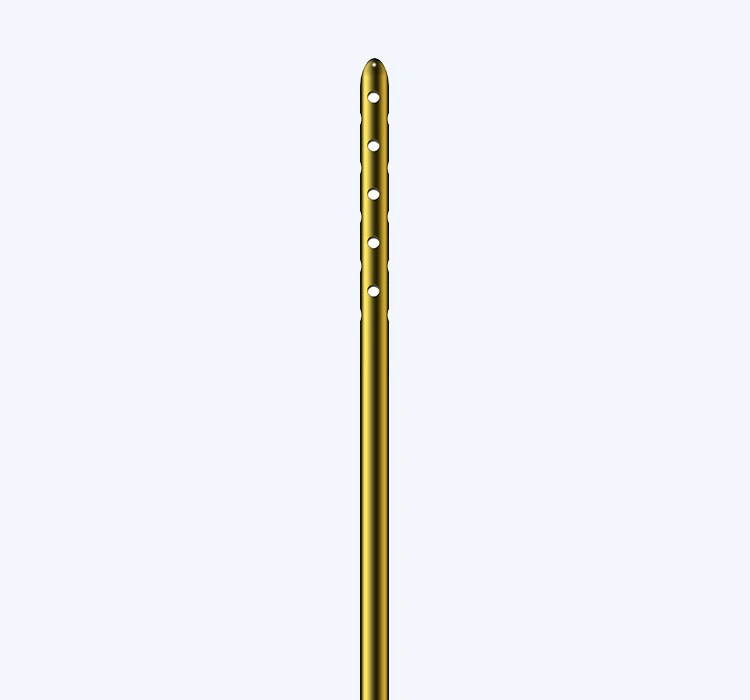

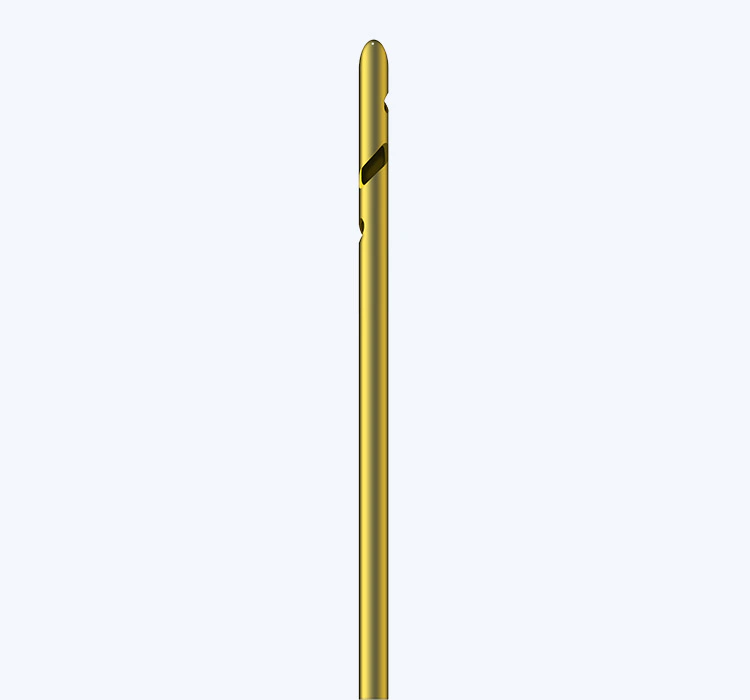

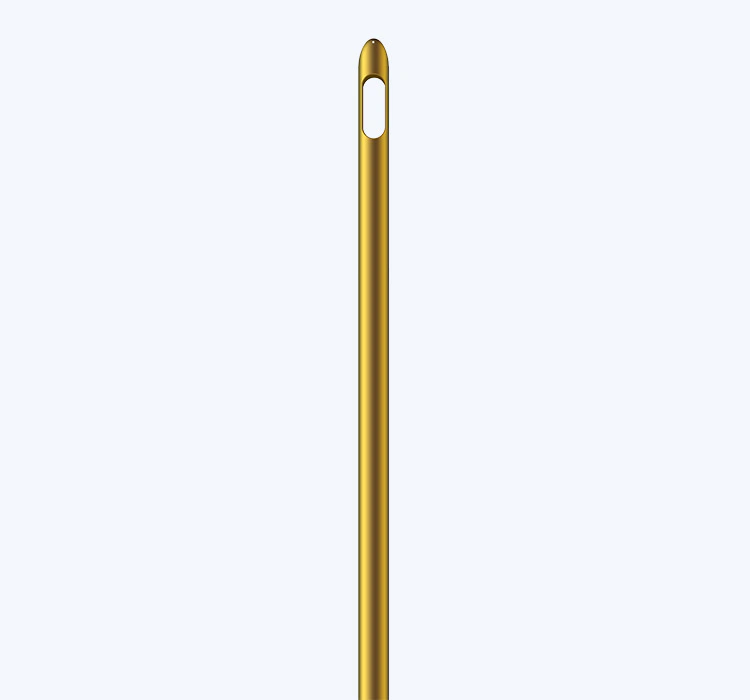

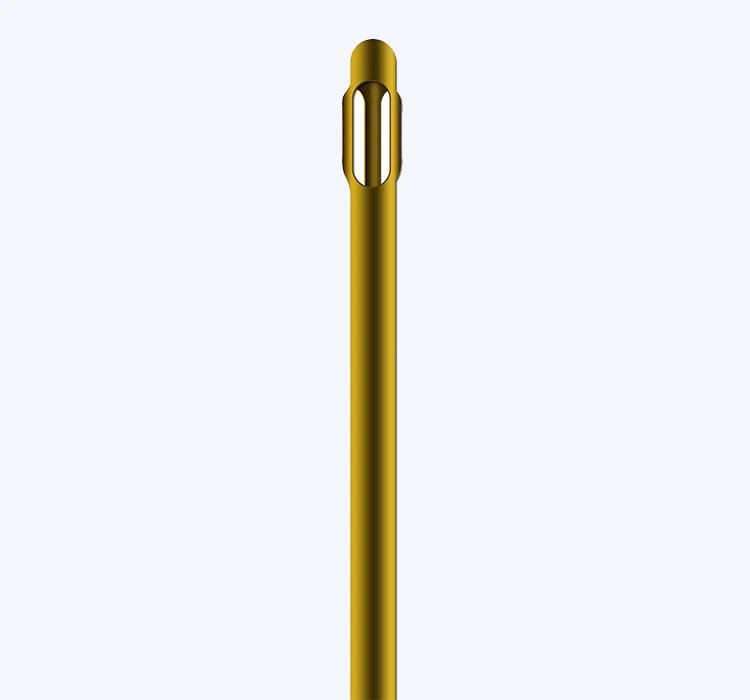

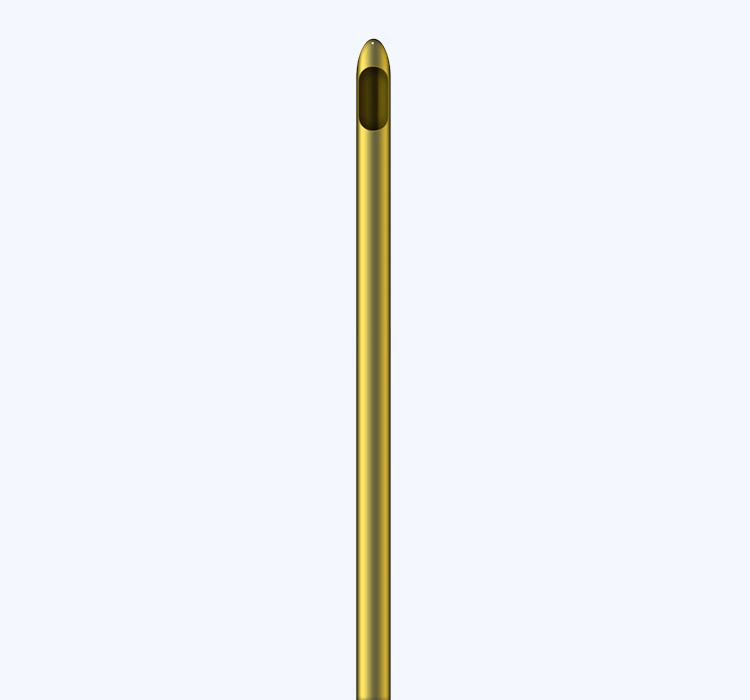

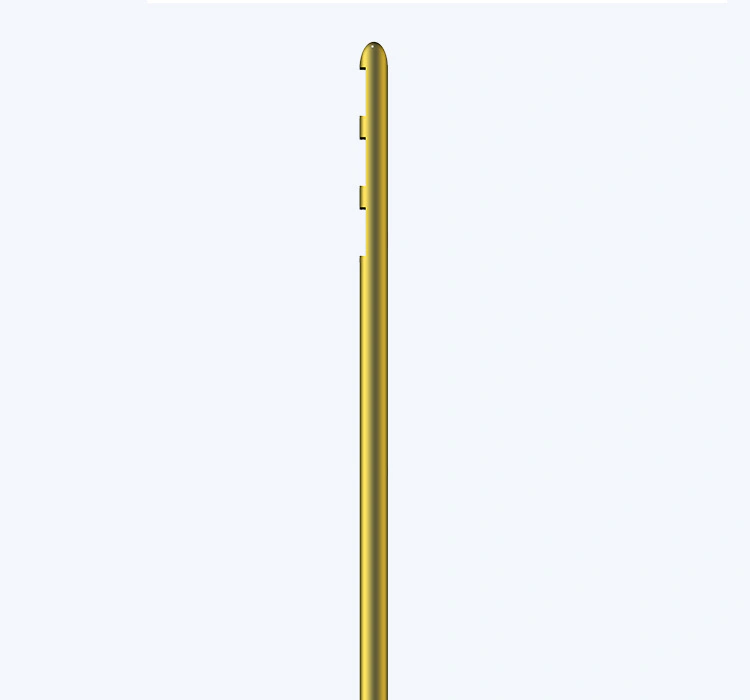

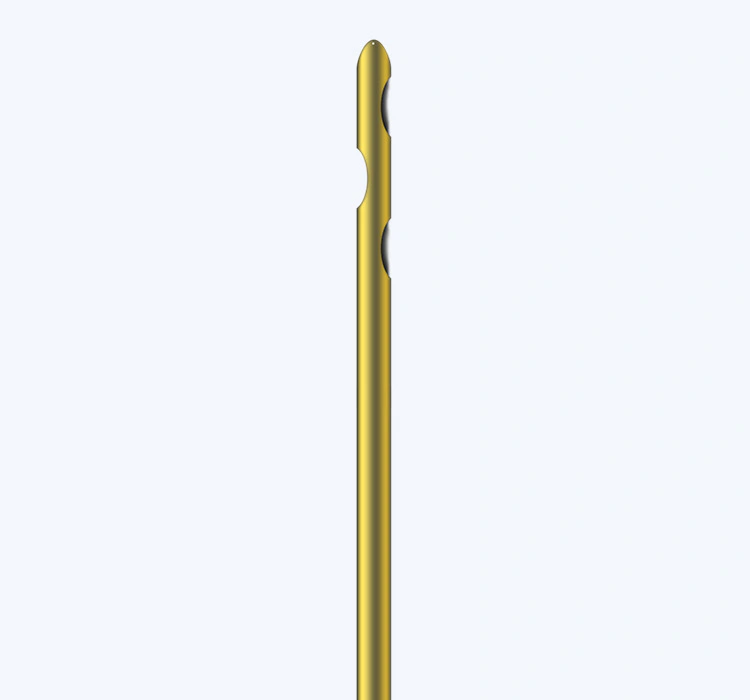

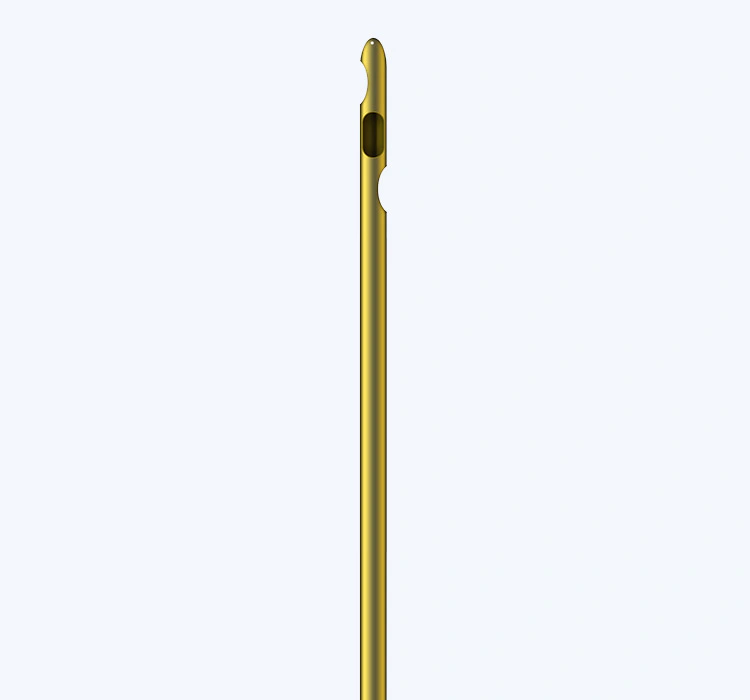

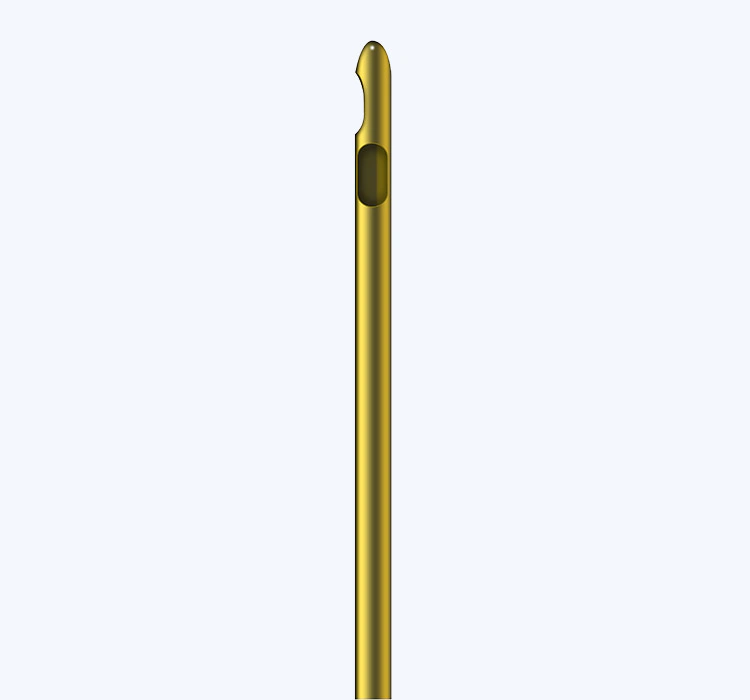

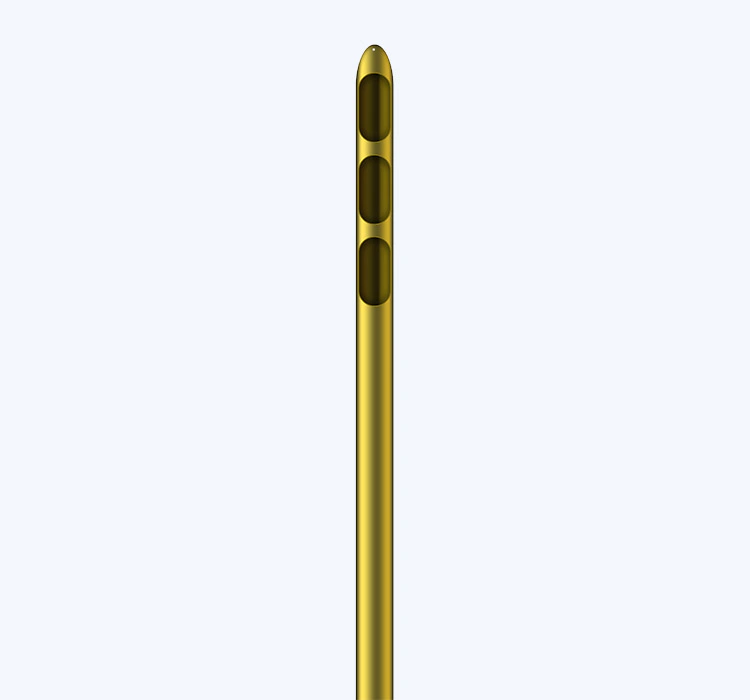

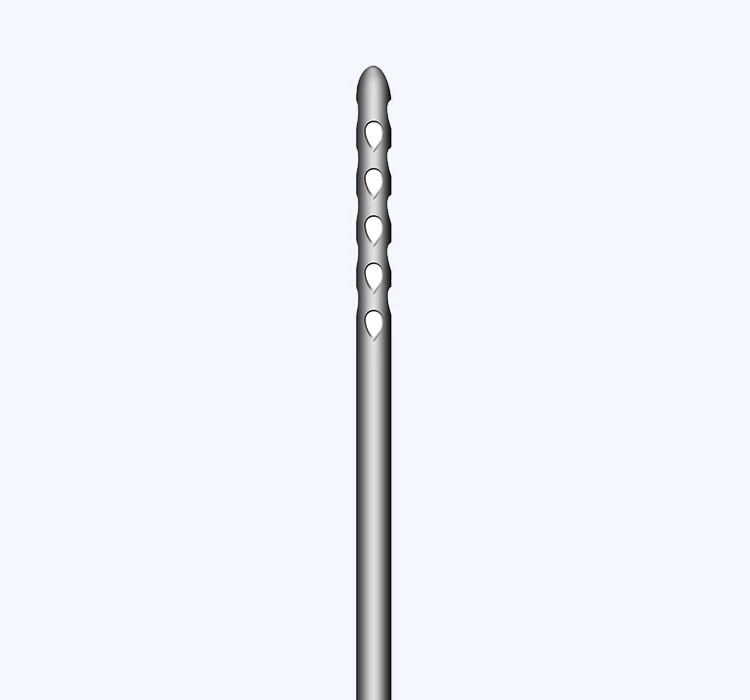

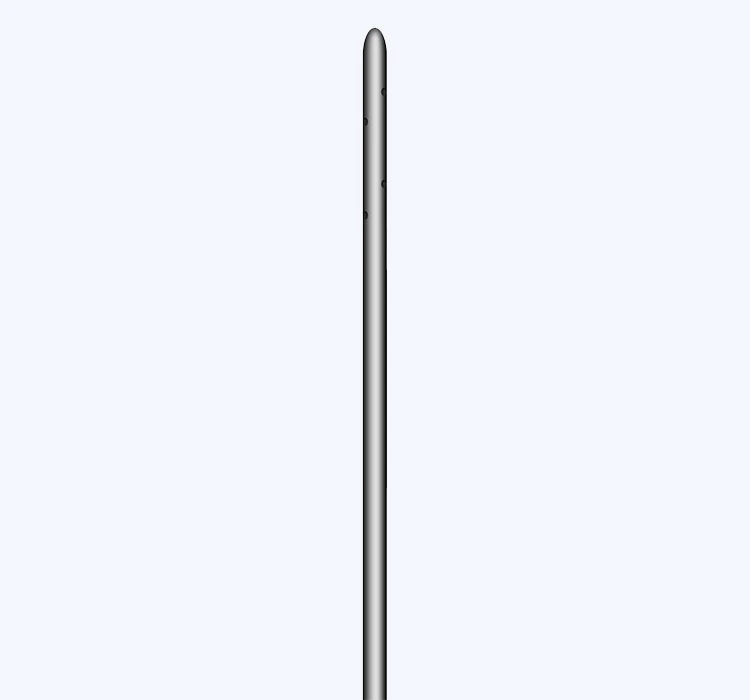

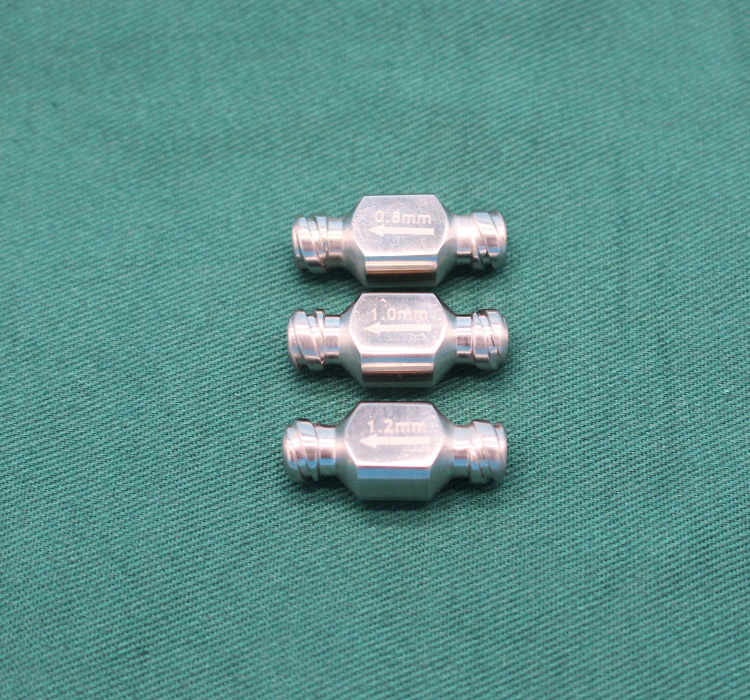

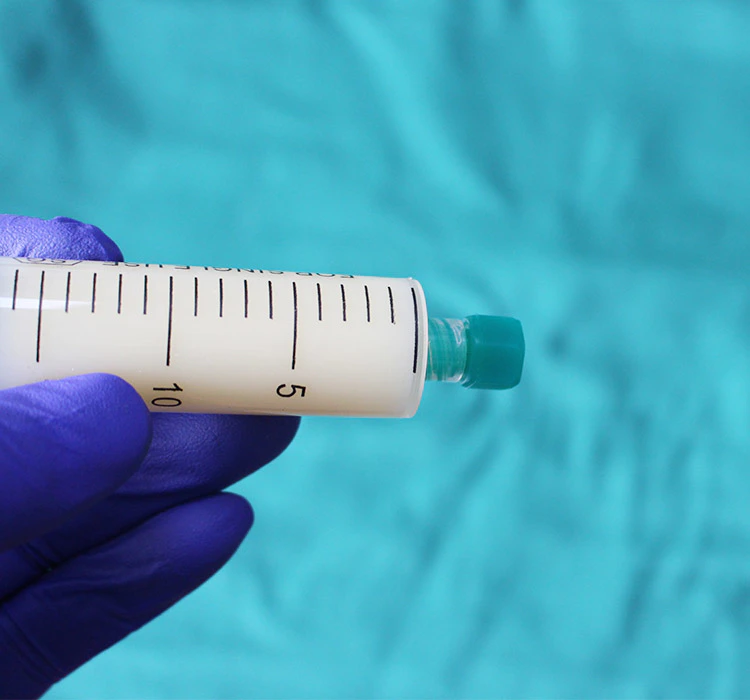

Dino Medical Instruments has come a long and far way in developing and manufacturing nano cannula transfer. We have made ourselves well known to the market. As one of Dino Medical Instruments 's multiple product series, micro cannulas series enjoy a relatively high recognition in the market. The product will not release harmful substances if used to hold acid and alkali food. The materials used in it features chemical inertness and they are unreactive with other chemicals. The length of this product can be customized according to needs. The offered product is valued for their huge benefits like compatibility and usability.

We strive to achieve our sustainability goals. We take steps to reduce greenhouse gas emissions, energy consumption, solid landfill waste, and water consumption.

Dino Medical Instruments has come a long and far way in developing and manufacturing nano cannula transfer. We have made ourselves well known to the market. As one of Dino Medical Instruments 's multiple product series, micro cannulas series enjoy a relatively high recognition in the market. The product will not release harmful substances if used to hold acid and alkali food. The materials used in it features chemical inertness and they are unreactive with other chemicals. The length of this product can be customized according to needs. The offered product is valued for their huge benefits like compatibility and usability.

We strive to achieve our sustainability goals. We take steps to reduce greenhouse gas emissions, energy consumption, solid landfill waste, and water consumption.

Custom message

Español

Español

Sales Manager : Kelly Zhou

Sales Manager : Kelly Zhou Email :

Email :  WhatsApp : +86 18067965386

WhatsApp : +86 18067965386