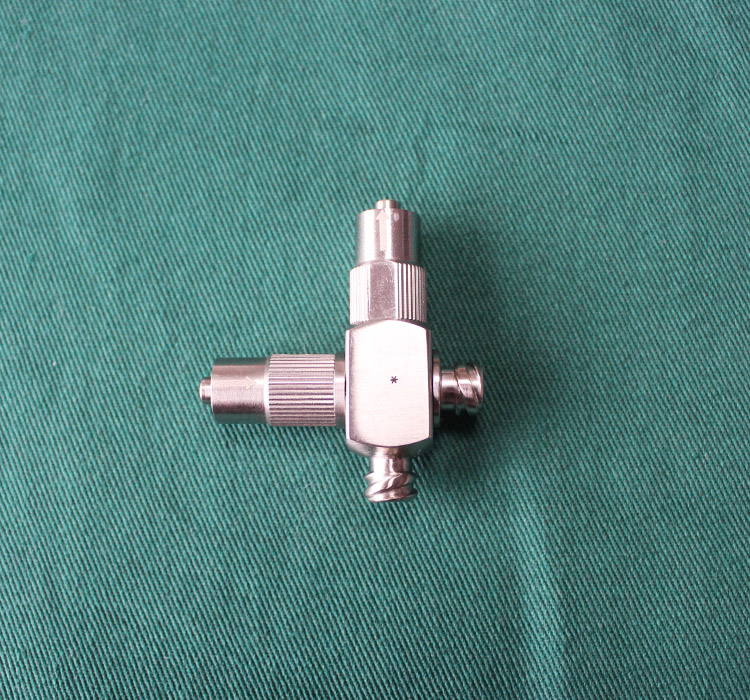

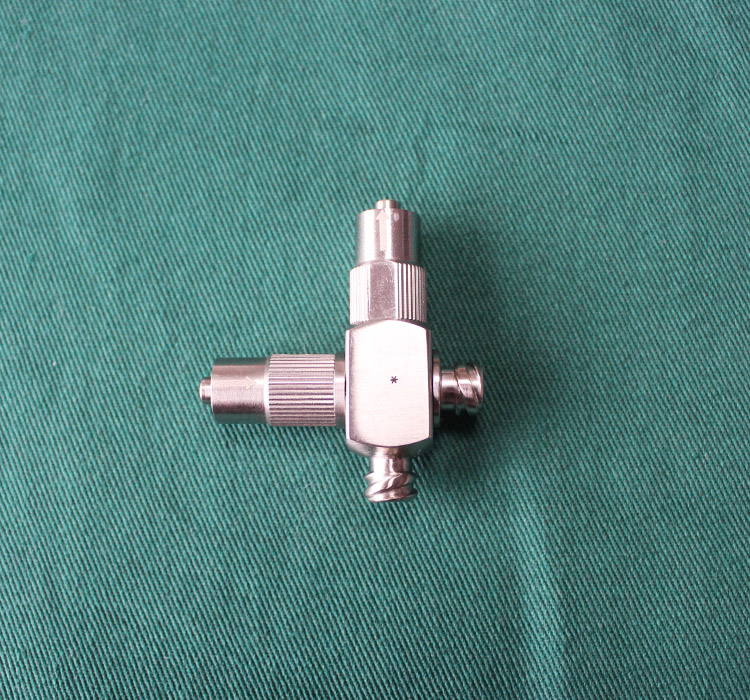

What standards are followed during fat grafting cannula production?

2022-02-14

The manufacturing of fat grafting cannula is not merely in accordance with the business norm, but also operates based on the international standard. Strict standardized manufacturing process facilitates the secure operation and rigorous guarantee of the goods. Compared with other producers, Hangzhou Dino Medical Instruments Co., Ltd.has been put quality first to carry out the production process. This guarantees the smooth manufacturing procedure and efficient business operation from selecting raw materials to selling products.

Dino Medical Instruments is a well-known Chinese company engaged in the development, manufacture, distribution, and marketing of high-quality injection needle. As one of Dino Medical Instruments 's multiple product series, micro cannulas series enjoy a relatively high recognition in the market. Dino plastic surgery machines is made by using good quality materials under the supervision of the professionals. Thanks to its tissue-friendly design, the product can decrease postoperative pain, ecchymoses, and edema. This product provides a healthy cooking way. Made from 100% natural mineral materials, it contains no chemical elements or heavy metals. Its streamlined design can effectively reduce tissue damage of the patients.

We have launched a series of sustainability initiatives. For example, we minimize our carbon footprint by using electricity more efficiently and reduce greenhouse gas emissions by minimizing waste.

Dino Medical Instruments is a well-known Chinese company engaged in the development, manufacture, distribution, and marketing of high-quality injection needle. As one of Dino Medical Instruments 's multiple product series, micro cannulas series enjoy a relatively high recognition in the market. Dino plastic surgery machines is made by using good quality materials under the supervision of the professionals. Thanks to its tissue-friendly design, the product can decrease postoperative pain, ecchymoses, and edema. This product provides a healthy cooking way. Made from 100% natural mineral materials, it contains no chemical elements or heavy metals. Its streamlined design can effectively reduce tissue damage of the patients.

We have launched a series of sustainability initiatives. For example, we minimize our carbon footprint by using electricity more efficiently and reduce greenhouse gas emissions by minimizing waste.

Custom message

Español

Español

Sales Manager : Kelly Zhou

Sales Manager : Kelly Zhou Email :

Email :  WhatsApp : +86 18067965386

WhatsApp : +86 18067965386